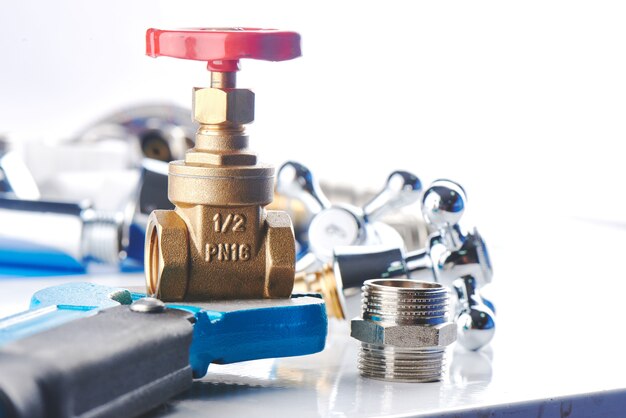

Valves play a crucial role in various industries, regulating the flow of liquids, gases, and slurries within different systems. Whether used in industrial manufacturing, oil and gas, water treatment, or chemical processing, selecting the right valve is essential for optimal system performance, efficiency, and safety. This comprehensive guide will help you navigate the different types of valves, their applications, selection criteria, and factors to consider before making a purchase.

Understanding Valves and Their Importance

A valve is a mechanical device used to control the flow and pressure of a fluid by opening, closing, or partially obstructing different passageways. Depending on the design and application, valves serve different functions such as isolation, regulation, non-return, and pressure relief. Choosing the right valve type ensures operational efficiency, minimizes downtime, and enhances system safety.

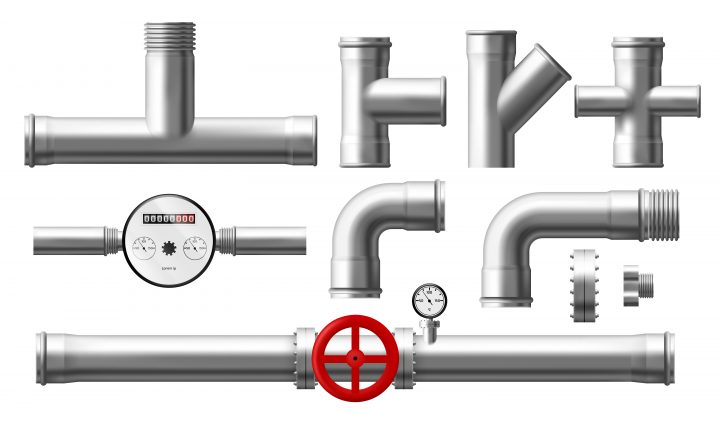

Types of Valves

There are various types of valves available in the market, each designed for specific functions. Below are the most common types:

1. Gate Valves

Gate valves are primarily used for on-off control of fluid flow. They have a simple design with a gate-like disc that moves up and down to allow or restrict fluid passage. These valves are commonly used in applications where minimal pressure drop and full flow are required.

Advantages:

- Low pressure drop when fully open

- Suitable for bi-directional flow

- Provides tight sealing

Disadvantages:

- Slow operation due to multi-turn movement

- Not suitable for throttling applications

2. Globe Valves

Globe valves are used for throttling and regulating flow. Their design includes a movable disc and a stationary ring seat inside a spherical body. These valves provide precise control and are widely used in steam applications.

Advantages:

- Good throttling capabilities

- Quick operation

- Effective in high-pressure applications

Disadvantages:

- Higher pressure drop compared to gate valves

- Requires frequent maintenance due to wear

3. Ball Valves

Ball valves use a spherical disc to control the flow of fluid. They are highly durable and provide a tight seal, making them ideal for applications requiring quick shutoff.

Advantages:

- Fast operation

- Reliable sealing

- Low maintenance

Disadvantages:

- Not suitable for throttling

- Prone to damage if used with slurries

4. Butterfly Valves

Butterfly valves use a rotating disc to control fluid flow. They are lightweight and compact, making them ideal for large-diameter applications.

Advantages:

- Quick operation

- Compact and space-saving

- Cost-effective

Disadvantages:

- Limited throttling capabilities

- Potential pressure drop

5. Check Valves

Check valves, or non-return valves, allow fluid to flow in one direction only, preventing backflow. They are commonly used in pipelines to prevent reverse flow and system contamination.

Advantages:

- Prevents backflow

- Automatic operation

- Low maintenance

Disadvantages:

- Can cause water hammer if not properly sized

- Limited control over flow

6. Diaphragm Valves

Diaphragm valves use a flexible diaphragm to regulate flow. They are commonly used in food processing, pharmaceuticals, and chemical applications.

Advantages:

- Suitable for handling corrosive and abrasive fluids

- Tight shutoff capability

- Minimal maintenance

Disadvantages:

- Limited to low-pressure applications

- Diaphragm wear over time

7. Solenoid Valves

Solenoid valves use electromagnetic coils to control fluid flow. These valves are widely used in automation and control systems.

Advantages:

- Fast response time

- Remote operation possible

- Energy-efficient

Disadvantages:

- Requires electricity

- Limited to specific pressure and temperature ranges

Factors to Consider When Choosing a Valve

Selecting the right valve for your needs requires careful consideration of several factors:

1. Application Requirements

Determine the purpose of the valve—whether it’s for isolation, throttling, or backflow prevention. Different applications require different valve types.

2. Fluid Type

Consider the nature of the fluid—liquid, gas, or slurry. Corrosive, abrasive, and high-viscosity fluids may require specialized materials.

3. Pressure and Temperature Ratings

Ensure the selected valve can withstand the operating pressure and temperature of your system to avoid failures.

4. Flow Control Requirements

If precise flow control is needed, opt for a valve with throttling capabilities, such as a globe valve.

5. Material Selection

Valve materials should be compatible with the fluid and operating conditions. Common materials include:

- Stainless Steel (corrosion resistance)

- Brass (general applications)

- Cast Iron (cost-effective for water systems)

- PVC (chemical resistance)

6. End Connections

Valves come with different end connections such as flanged, threaded, welded, or push-to-connect. Choose based on installation ease and compatibility.

7. Maintenance and Lifecycle Costs

Consider the long-term cost of maintenance and potential downtime. Some valves require frequent maintenance, while others offer extended service life.

Valve Standards and Certifications

When purchasing valves, ensure they meet relevant industry standards and certifications such as:

- ANSI (American National Standards Institute)

- API (American Petroleum Institute)

- ISO (International Organization for Standardization)

- ASME (American Society of Mechanical Engineers)

Compliance with these standards ensures safety, performance, and reliability.

Where to Buy Quality Valves

With numerous manufacturers and suppliers in the market, finding the right valve can be challenging. Consider using trusted online B2B marketplaces for engineering products, such as Enggpro.

Conclusion: Why Choose Enggpro for Your Valve Needs?

Enggpro is a leading B2B marketplace for engineering products and services, connecting buyers with verified suppliers, manufacturers, and service providers worldwide. Key features include:

- Verified Suppliers: Access a network of pre-vetted suppliers ensuring quality and reliability.

- Diverse Product Range: Browse a wide variety of industrial valves catering to different industries.

- Competitive Pricing: Compare prices and get the best deals from multiple suppliers.

- Seamless Procurement: Streamlined ordering, quotations, and delivery management.

- Expert Support: Get guidance from industry experts to choose the right valve for your application.

For a hassle-free valve procurement experience, explore Enggpro and ensure you get the best quality valves suited for your operational needs.

By following this guide, valve buyers can make informed decisions and select the best valves for their applications, ensuring efficiency, reliability, and long-term performance.