Introduction

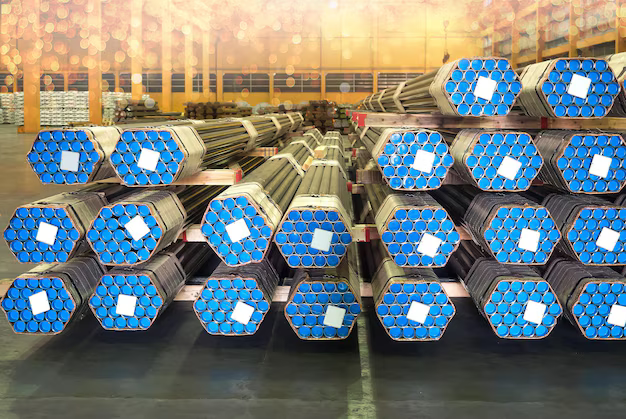

The steel tubes industry in India plays a crucial role in the country’s economic and industrial growth. Steel tubes are used in multiple sectors, including construction, infrastructure, automotive, oil and gas, and manufacturing. India is one of the largest producers and consumers of steel tubes, with a steadily growing demand due to rapid urbanization and industrialization. However, the industry faces several challenges, such as fluctuating raw material prices, environmental concerns, import competition, and logistical constraints. This article explores the key challenges and provides strategic solutions to strengthen the steel tubes sector in India.

Overview of the Steel Tubes Industry in India

The Indian steel tubes industry is diverse and comprises various types of tubes, such as:

- Seamless Steel Tubes: Used in applications requiring high strength and durability, such as oil and gas pipelines and heavy machinery.

- Welded Steel Tubes: Commonly used in construction, furniture, and general engineering.

- Galvanized Steel Tubes: Coated with zinc for corrosion resistance, these tubes are widely used in water supply systems and fencing.

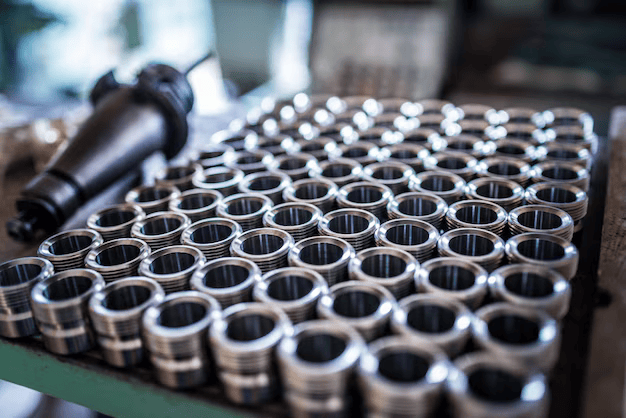

- Precision Steel Tubes: Used in the automotive and aerospace industries for high-precision applications.

With government initiatives like ‘Make in India’ and investments in infrastructure development, the demand for steel tubes has surged. However, the industry must overcome several challenges to ensure sustainable growth.

Challenges Facing the Steel Tubes Industry in India

1. Raw Material Availability and Pricing

The steel tubes industry relies heavily on raw materials like iron ore and coking coal. The fluctuating global market prices and supply chain disruptions impact production costs. Additionally, India depends on imports for high-grade coking coal, making the industry vulnerable to international price variations.

2. Technological Adoption

Many small and medium-sized enterprises (SMEs) in the steel tubes industry still use outdated manufacturing processes. The lack of advanced technology adoption results in inefficiencies in production, lower product quality, and higher operational costs. The integration of Industry 4.0 solutions such as automation, artificial intelligence (AI), and digital supply chain management is crucial for enhancing productivity.

3. Environmental Concerns

Steel production is energy-intensive and contributes significantly to carbon emissions. With increasing pressure from environmental regulations and sustainability goals, the industry must adopt greener technologies. The shift towards energy-efficient production methods, such as electric arc furnaces and carbon capture technology, is necessary but requires substantial investment.

4. Import Competition and Trade Policies

The Indian steel tubes market faces intense competition from cheaper imports, particularly from China, South Korea, and Japan. Domestic manufacturers struggle to match the lower prices of imported products, affecting their profitability. While the government has imposed anti-dumping duties and safeguard measures, the industry still requires more robust trade policies to ensure fair competition.

5. Infrastructure and Logistics Challenges

Inefficient transportation networks and inadequate storage facilities add to the cost burden of steel tube manufacturers. Delays in logistics impact timely delivery to customers, affecting overall business operations. The need for improved rail and road connectivity is essential to streamline supply chains.

6. Regulatory Compliance and Taxation

Navigating complex regulations and high taxation structures adds to the operational challenges faced by steel tube manufacturers. Frequent changes in policies and compliance requirements create uncertainty, making long-term business planning difficult for the industry.

7. Skilled Labor Shortage

The steel tubes industry requires a skilled workforce for production, quality control, and technological advancements. However, there is a shortage of trained personnel in modern manufacturing techniques. Bridging the skill gap through vocational training programs and industry-academia collaborations is crucial for sustainable growth.

Solutions and Strategic Initiatives

1. Enhancing Raw Material Security

To reduce dependency on imported raw materials, India needs to boost domestic mining and invest in alternative materials. Encouraging research and development in alternative alloys can help mitigate the impact of raw material price fluctuations.

2. Technological Advancements

- Automation and AI Integration: Implementing robotics and AI-driven production processes can enhance efficiency and precision.

- Digital Supply Chains: Using blockchain and IoT-based tracking systems can improve inventory management and reduce production delays.

- Advanced Welding Techniques: Adopting high-frequency induction welding and laser welding can improve the quality and durability of welded steel tubes.

3. Sustainable Manufacturing Practices

- Energy-efficient Production: Using renewable energy sources like solar and wind power for manufacturing can lower carbon footprints.

- Recycling and Waste Management: Encouraging steel recycling and adopting zero-waste policies can make the industry more environmentally friendly.

- Green Steel Initiatives: The government should introduce incentives for manufacturers adopting sustainable practices, such as reduced taxes or subsidies for eco-friendly steel production.

4. Trade Policy Reforms

- Anti-Dumping Measures: Strengthening trade policies to protect domestic manufacturers from unfair foreign competition.

- Export Promotion: Encouraging steel tube exports through incentives and trade agreements with global markets.

- Tariff Adjustments: Implementing fair import tariffs to balance domestic and international market competition.

5. Infrastructure Development

- Improved Transportation Networks: Investing in railway and highway projects to facilitate seamless logistics.

- Modern Warehousing: Developing better storage facilities for raw materials and finished products to optimize supply chain operations.

- Smart Port Facilities: Enhancing port efficiency for faster export and import processing.

6. Policy Simplification and Ease of Doing Business

- Tax Reforms: Introducing tax benefits for steel tube manufacturers to improve profitability.

- Streamlined Regulations: Reducing bureaucratic red tape and simplifying compliance procedures.

- Financial Support: Providing low-interest loans and subsidies to SMEs in the steel industry for technological upgrades.

7. Workforce Development

- Skill Development Programs: Establishing training centers to equip workers with modern manufacturing skills.

- Industry-Academia Collaboration: Partnering with technical institutes to provide hands-on training in steel tube production.

- Apprenticeship Programs: Encouraging on-the-job training for new workers to enhance their expertise.

See Also Steel Tubes Manufacturers in India

Leading Steel Tubes Manufacturers in India

India is home to several renowned steel tube manufacturers that cater to both domestic and international markets. Here are some of the leading companies:

1. Hitech Metal and Tubes

- Specializes in high-quality steel tubes with a focus on durability and precision engineering.

- Supplies to industries such as construction, automotive, and oil & gas.

2. Maharashtra Seamless Ltd

- Known for producing seamless pipes and tubes using advanced technology.

- Provides products to the oil and gas, power, and engineering sectors.

3. Tata Steel

- Offers a wide range of steel tubes, including structural and conveyance tubes.

- Focuses on sustainable manufacturing and high-quality standards.

4. APL Apollo Tubes Limited

- India’s largest producer of structural steel tubes.

- Supplies to real estate, infrastructure, and industrial applications.

5. Jindal SAW Ltd

- Specializes in manufacturing submerged arc welded (SAW) pipes and tubes.

- Key supplier to the oil and gas, water, and transportation sectors.

See Also Rise of Steel Tubes Manufacturers in India: Innovations and Industry Trends

Conclusion

The steel tubes industry in India is poised for significant growth, driven by infrastructure development and increasing demand across multiple sectors. However, challenges such as raw material dependency, technological gaps, and environmental concerns must be addressed through strategic initiatives.

By embracing advanced manufacturing technologies, adopting sustainable practices, and implementing supportive government policies, the industry can overcome these challenges and strengthen its global presence. Moreover, leading manufacturers continue to innovate and expand, ensuring that India remains a key player in the global steel tubes market.

As India moves towards becoming a manufacturing hub, the steel tubes industry will play a vital role in supporting the nation’s industrial expansion and economic progress.

For a comprehensive list of steel tube manufacturers in India, along with detailed features and more information, please visit Enggpro’s directory of steel tube manufacturers. Enggpro provides an extensive database of verified manufacturers, facilitating informed decision-making for businesses seeking quality steel tube products.