Valves are pivotal components across numerous industrial sectors, controlling the flow of fluids and gases to ensure efficient and safe operations. As India continues to grow as a major industrial hub, the demand for high-quality valves has surged, making it crucial for industries to partner with reliable manufacturers. This comprehensive guide aims to provide an in-depth look at the top valve manufacturers in India for 2024, offering valuable insights to help you make informed decisions.

The Valve Industry Landscape in India

The valve manufacturing sector in India is a dynamic and expanding industry driven by various factors. Understanding the current landscape can help you appreciate the significance of choosing the right manufacturer.

Industrial Growth and Infrastructure Development

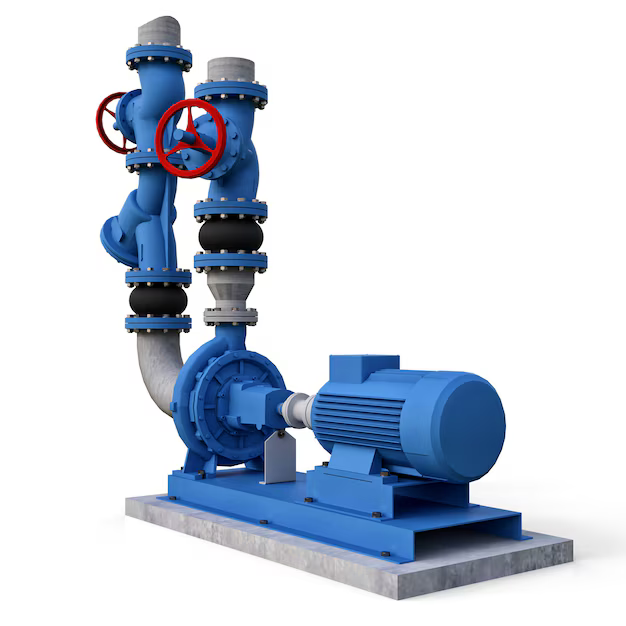

India’s rapid industrialization and infrastructure development have significantly contributed to the growth of the valve industry. Major infrastructure projects, including water treatment facilities, sewage systems, and urban development, require efficient valve solutions. Additionally, the expansion of industries such as oil & gas, power generation, and chemical processing has increased the demand for high-performance valves.

Technological Advancements

The valve industry in India has seen considerable advancements in technology and manufacturing processes. Modern valve designs incorporate cutting-edge materials and innovative engineering to enhance performance, reliability, and efficiency. These advancements are crucial for meeting the stringent demands of various industrial applications, including high-pressure and high-temperature environments.

Regulatory Standards

Compliance with international and national standards is essential in the valve manufacturing industry. Manufacturers are required to adhere to standards such as ISO, API, and ASME to ensure the quality and safety of their products. Understanding these standards helps in evaluating the credibility of valve manufacturers.

Top Valve Manufacturers in India

Here’s a detailed look at some of the leading valve manufacturers in India. These companies are renowned for their high-quality products, innovative solutions, and industry expertise.

1. Apollo Valves

Overview: Apollo Valves is a prominent name in the Indian valve manufacturing industry, offering a diverse range of valves including gate, globe, ball, and check valves. Their products are widely used in sectors such as waterworks, oil & gas, and industrial applications.

Key Features:

- Quality Assurance: Apollo Valves is committed to maintaining high standards of quality. They adhere to international certifications such as ISO and API, ensuring that their products meet global quality benchmarks.

- Product Range: Apollo Valves provides both standard and customized valve solutions, catering to specific application requirements. Their extensive product range allows for flexibility in meeting diverse needs.

- Technological Innovation: The company incorporates advanced design and materials in their valves to enhance durability and performance. Their focus on technological innovation ensures that their products are at the forefront of the industry.

Applications: Water treatment plants, oil & gas pipelines, industrial processes.

2. Forbes Marshall

Overview: Forbes Marshall is a leading manufacturer specializing in process control valves and automation solutions. With a strong presence in industries such as power, chemicals, and water treatment, Forbes Marshall is known for its engineering excellence and product reliability.

Key Features:

- Comprehensive Solutions: Forbes Marshall offers a wide range of valves including control, isolation, and safety valves. Their product offerings are designed to meet the specific needs of various industrial processes.

- Innovation: The company focuses on incorporating the latest technology in valve design and manufacturing. This commitment to innovation ensures that their products are efficient and reliable.

- Global Presence: Forbes Marshall’s products are not only used in India but also have a significant presence in international markets. Their adherence to global quality standards enhances their reputation worldwide.

Applications: Power generation, chemical processing, water treatment.

3. L&T Valves

Overview: Larsen & Toubro (L&T) is a major player in the valve manufacturing industry, known for its high-quality products and engineering expertise. L&T Valves offers a broad range of valves for various industrial applications, including gate, globe, ball, check, and butterfly valves.

Key Features:

- Diverse Product Line: L&T manufactures a wide array of valves designed for different industrial applications. Their product range includes valves for high-pressure and high-temperature environments.

- Engineering Excellence: The company’s valves are engineered to perform reliably in demanding conditions. L&T’s focus on engineering excellence ensures that their products meet the highest standards of performance.

- Quality Control: L&T follows stringent quality control measures throughout the manufacturing process, ensuring that their valves are durable and dependable.

Applications: Oil & gas, petrochemicals, power generation.

4. KSB India

Overview: KSB India is a leading manufacturer of valves and pumps, offering a comprehensive range of products for water, wastewater, and industrial applications. Known for its quality and innovation, KSB India has established itself as a key player in the valve industry.

Key Features:

- Product Range: KSB India provides a variety of valves including gate, globe, ball, and check valves. Their product range is designed to cater to the needs of different industrial sectors.

- Innovation and Quality: The company emphasizes technological innovation and quality in its valve manufacturing processes. Their products are known for their durability and efficiency.

- Service and Support: KSB offers comprehensive after-sales support and services, including installation, maintenance, and troubleshooting.

Applications: Water supply systems, wastewater treatment, industrial processes.

5. R&B Valves

Overview: R&B Valves is a prominent manufacturer specializing in industrial valves for sectors such as oil & gas, chemicals, and power generation. Known for its robust and reliable valve solutions, R&B Valves caters to a wide range of industrial applications.

Key Features:

- High Performance: R&B Valves provides products designed to perform effectively under extreme conditions. Their valves are built to withstand high pressures and temperatures.

- Custom Solutions: The company offers customized valve solutions tailored to specific industry requirements. This flexibility allows them to meet the unique needs of their clients.

- Quality Standards: R&B Valves adheres to national and international quality standards, ensuring that their products are reliable and durable.

Applications: Oil & gas, chemical processing, power generation.

6. Metso India

Overview: Metso India, part of the global Metso Group, offers a diverse range of industrial valves and solutions. Known for its advanced technology and high-quality products, Metso India serves various industries including mining, oil & gas, and energy.

Key Features:

- Innovative Technology: Metso incorporates cutting-edge technology into its valve designs, enhancing performance and reliability. Their products are known for their advanced features and durability.

- Global Expertise: With a global presence, Metso India leverages international expertise to provide high-quality valve solutions that meet global standards.

- Customer Focus: The company is committed to understanding and addressing the specific needs of its customers, providing tailored solutions and support.

Applications: Mining, oil & gas, energy.

Factors to Consider When Choosing a Valve Manufacturer

Selecting the right valve manufacturer is crucial for ensuring the efficiency and reliability of your industrial operations. Here are some key factors to consider:

1. Product Quality and Standards

Certification: Ensure that the manufacturer adheres to international quality standards such as ISO, API, and ASME. Certifications indicate that the manufacturer meets rigorous quality benchmarks.

Material and Construction: Evaluate the materials used in valve construction to ensure they are suitable for your application. High-quality materials contribute to the durability and performance of the valves.

2. Manufacturing Capabilities

Production Capacity: Assess the manufacturer’s production capacity to ensure they can meet your order requirements. A manufacturer with a high production capacity can handle large orders and ensure timely delivery.

Technological Advancements: Consider the manufacturer’s use of advanced technologies and manufacturing processes. Modern technology can enhance the precision and quality of the valves.

3. Industry Experience and Expertise

Industry Focus: Look for manufacturers with experience in your specific industry. Industry-focused manufacturers are more likely to understand the unique requirements and challenges of your application.

Customer Reviews: Research customer reviews and testimonials to gauge the manufacturer’s reputation and reliability. Positive feedback from other customers can provide valuable insights into the manufacturer’s capabilities.

4. Customization and Flexibility

Product Customization: Determine if the manufacturer can provide customized valve solutions tailored to your specific needs. Customization can be essential for meeting unique operational requirements.

Flexibility: Assess the manufacturer’s ability to accommodate changes in order volume or product specifications. A flexible manufacturer can adapt to evolving needs and requirements.

5. After-Sales Support and Service

Technical Support: Ensure that the manufacturer provides adequate technical support and assistance for installation, maintenance, and troubleshooting. Effective after-sales support can enhance the performance and longevity of the valves.

Warranty and Guarantees: Check for warranties or guarantees that cover product defects or performance issues. A strong warranty can provide peace of mind and protection against potential issues.

6. Pricing and Value

Competitive Pricing: Compare prices from different manufacturers to ensure you receive a competitive offer. However, focus on the overall value rather than just cost. Consider factors such as product quality, performance, and support.

Value-Added Services: Consider additional services offered by the manufacturer, such as technical training, expedited shipping, or maintenance services. Value-added services can enhance the overall value of your purchase.

See Also The Ultimate Guide to Understanding Different Types of Valves

Future Trends in the Valve Industry

As industries evolve and new technologies emerge, the valve industry is also undergoing significant changes. Here are some key trends to watch for in 2024 and beyond:

1. Increased Emphasis on Sustainability

Sustainability is becoming a major focus in industrial manufacturing, including the valve industry. Manufacturers are increasingly adopting eco-friendly practices and materials to reduce their environmental impact. This includes developing valves that are more energy-efficient and have a lower carbon footprint.

2. Advancements in Smart Valve Technology

The integration of smart technology into valve systems is gaining traction. Smart valves equipped with sensors and IoT capabilities provide real-time monitoring and control, enhancing efficiency and reducing maintenance costs. These advancements are expected to drive innovation in valve design and functionality.

3. Growth of Automation and Digitalization

Automation and digitalization are transforming industrial processes, including valve operations. Automated valve systems offer improved precision, reduced manual intervention, and enhanced process control. The adoption of digital technologies is expected to continue growing, influencing valve manufacturing and application.

4. Focus on Industry-Specific Solutions

Manufacturers are increasingly focusing on providing industry-specific valve solutions to address unique challenges and requirements. This includes developing specialized valves for applications such as high-temperature processes, corrosive environments, and critical safety systems.

5. Expansion of Global Markets

As Indian valve manufacturers expand their global presence, they are increasingly competing in international markets. This expansion is driven by the demand for high-quality valves and the need to meet global industry standards. Manufacturers are leveraging their expertise to cater to a broader range of applications and markets.

Conclusion

The valve manufacturing industry in India is characterized by its diversity, technological advancements, and growing demand. The manufacturers highlighted in this guide represent some of the top players in the industry, known for their high-quality products, innovative solutions, and commitment to excellence.

When selecting a valve manufacturer, it is essential to consider factors such as product quality, manufacturing capabilities, industry experience, and after-sales support. By evaluating these factors and staying informed about industry trends, you can make well-informed decisions and partner with a manufacturer that meets your specific needs.

As the valve industry continues to evolve, staying updated on advancements and trends will help you navigate the market effectively and choose the best solutions for your industrial applications. Whether you are involved in water treatment, oil & gas, power generation, or any other sector, the right valve manufacturer can play a crucial role in ensuring the efficiency and reliability of your operations.

To find top valve manufacturers in India, consider exploring Enggpro, a platform that connects you with a wide range of valve manufacturers and suppliers. Enggpro can help you find reliable manufacturers that meet your specific requirements, ensuring that you make informed decisions and partner with the best in the industry.

Disclaimer: This blog is created based on information sourced from the internet. While every effort has been made to ensure the accuracy of the information, readers are advised to independently verify details before making any decisions. The blog is intended for informational purposes only and should not be considered as expert or professional advice.