Heat exchangers are critical components in a wide array of industries, facilitating the transfer of heat between two or more fluids without mixing them. From manufacturing to energy production, they enhance efficiency, reduce energy consumption, and support sustainable operations. This comprehensive guide will walk you through the essentials of heat exchangers, including their types, applications, and maintenance, and introduce a curated list of leading heat exchanger manufacturers in India from Enggpro.

What is a Heat Exchanger?

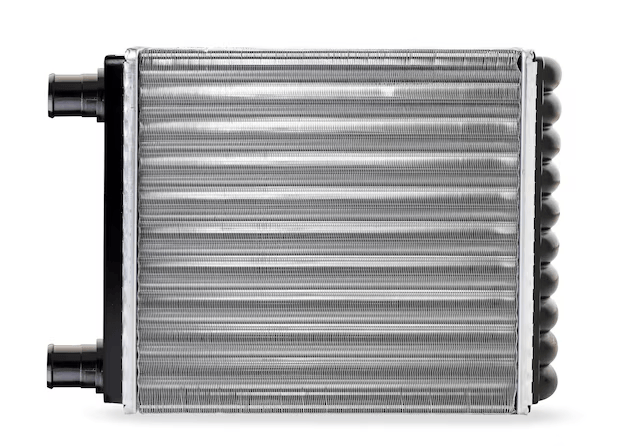

A heat exchanger is a device designed to transfer heat between two or more fluids (liquids, gases, or vapors) while preventing direct contact between them. By leveraging the temperature gradient between fluids, heat exchangers optimize energy usage in processes like cooling, heating, and energy recovery.

See Also Everything You Need To Know About Heat Exchangers

Types of Heat Exchangers

The design and working principles of heat exchangers vary depending on their application and medium of use. Here are the most common types:

1. Shell and Tube Heat Exchangers

- Structure: Consists of a series of tubes enclosed within a cylindrical shell.

- Application: Commonly used in industries like oil and gas, chemical processing, and power plants.

- Advantages:

- High-pressure handling capabilities.

- Durable and easy to clean.

2. Plate Heat Exchangers

- Structure: Comprised of thin, corrugated plates stacked together to create a series of channels.

- Application: Widely used in HVAC systems, food processing, and pharmaceuticals.

- Advantages:

- Compact and efficient.

- Easy to dismantle for cleaning and maintenance.

3. Air-Cooled Heat Exchangers

- Structure: Uses air as a cooling medium, typically with finned tubes.

- Application: Ideal for areas with limited water availability, such as petrochemical plants and refineries.

- Advantages:

- Water-independent operation.

- Suitable for outdoor applications.

4. Double Pipe Heat Exchangers

- Structure: Features one pipe inside another, with one fluid flowing through the inner pipe and the other through the annulus.

- Application: Found in smaller-scale applications like waste heat recovery systems.

- Advantages:

- Simple and cost-effective.

- Easy to maintain.

5. Plate-Fin Heat Exchangers

- Structure: Uses fins to increase surface area for heat transfer.

- Application: Common in aerospace, automotive, and cryogenic industries.

- Advantages:

- Lightweight and compact.

- High thermal efficiency.

See Also A Deep Dive into the Heat Exchanger Manufacturing Process: Insights from India’s Top Players

Applications of Heat Exchangers

Heat exchangers are versatile and find applications in diverse sectors:

- Industrial Manufacturing: Maintain optimal temperatures in chemical processes, metal refining, and plastic molding.

- Power Generation: Coolants in power plants and thermal energy recovery systems.

- HVAC Systems: Ensure efficient heating, ventilation, and air conditioning in residential and commercial buildings.

- Food and Beverage Industry: Pasteurization and cooling in food production.

- Automotive Sector: Radiators and intercoolers for engine efficiency.

- Oil and Gas Industry: Heat recovery and cooling processes in refineries.

Maintenance Tips for Heat Exchangers

Regular maintenance of heat exchangers is crucial for sustaining efficiency and prolonging their lifespan. Here are essential tips:

1. Inspect Regularly

- Monitor for signs of corrosion, leaks, and fouling.

- Check for unusual pressure drops and temperature inconsistencies.

2. Clean Periodically

- Use chemical cleaning to remove scale and deposits.

- Implement mechanical cleaning for stubborn debris in tubes or plates.

3. Prevent Fouling

- Employ anti-fouling coatings or treatment chemicals.

- Maintain proper fluid velocity to minimize deposit buildup.

4. Monitor Operating Conditions

- Ensure the system operates within recommended pressure and temperature ranges.

- Use sensors to detect any deviations.

5. Replace Worn Components

- Replace gaskets, seals, or corroded parts promptly.

- Consider upgrading to modern materials for better durability.

Conclusion

Heat exchangers are indispensable for efficient thermal management across industries. Their types, such as shell-and-tube, plate, and air-cooled designs, cater to diverse needs, while proper maintenance ensures long-term performance.

To support your industrial requirements, finding reliable manufacturers is crucial. Enggpro, a leading engineering marketplace, provides an extensive list of heat exchanger manufacturers in India.

Top Heat Exchanger Manufacturers in India on Enggpro

Here are some of the top heat exchanger manufacturers in India, curated from Enggpro:

1. ABC Heat Exchangers

- Features:

- Specializes in customizable shell-and-tube and plate heat exchangers.

- High-efficiency designs for industrial and HVAC applications.

- About:

Based in Mumbai, this company offers robust solutions with a focus on innovation and sustainability.

2. XYZ Thermal Solutions

- Features:

- Offers lightweight, compact heat exchangers with excellent thermal performance.

- Expertise in air-cooled systems for energy-intensive industries.

- About:

With state-of-the-art facilities in Pune, XYZ is a trusted partner for critical thermal management needs.

3. ThermoTech India

- Features:

- Advanced plate-fin exchangers for the aerospace and automotive sectors.

- Durable products built with corrosion-resistant materials.

- About:

Located in Chennai, ThermoTech India has a global footprint and delivers cutting-edge technology.

4. HeatFlow Engineers

- Features:

- Provides double-pipe and shell-and-tube solutions tailored for chemical and petrochemical industries.

- Focuses on energy efficiency and cost-effectiveness.

- About:

This Gujarat-based company emphasizes customer-centric designs and timely delivery.

5. EcoHeat Solutions

- Features:

- Specializes in environmentally friendly heat exchangers for the food and beverage industry.

- Compact designs ideal for limited spaces.

- About:

Headquartered in Delhi, EcoHeat Solutions prioritizes sustainability and regulatory compliance.

Explore these manufacturers on Enggpro to find the perfect heat exchanger tailored to your needs. Their detailed product listings and trusted reviews make it easy to make an informed choice.