Introduction:

Selecting the right steel plate stockist is crucial for the success of any construction or manufacturing project. With numerous suppliers claiming to offer the best products and services, navigating through the options can be overwhelming. In this essential guide, we’ll explore the key factors to consider when choosing a steel plate stockist to ensure that your project receives the quality materials and support it deserves.

1. Reputation and Reliability:

A reputable steel plate stockist should have a solid track record of reliability and integrity. Look for suppliers with positive reviews, testimonials from satisfied customers, and a history of delivering high-quality products on time. Additionally, inquire about their certifications and accreditations to ensure compliance with industry standards.

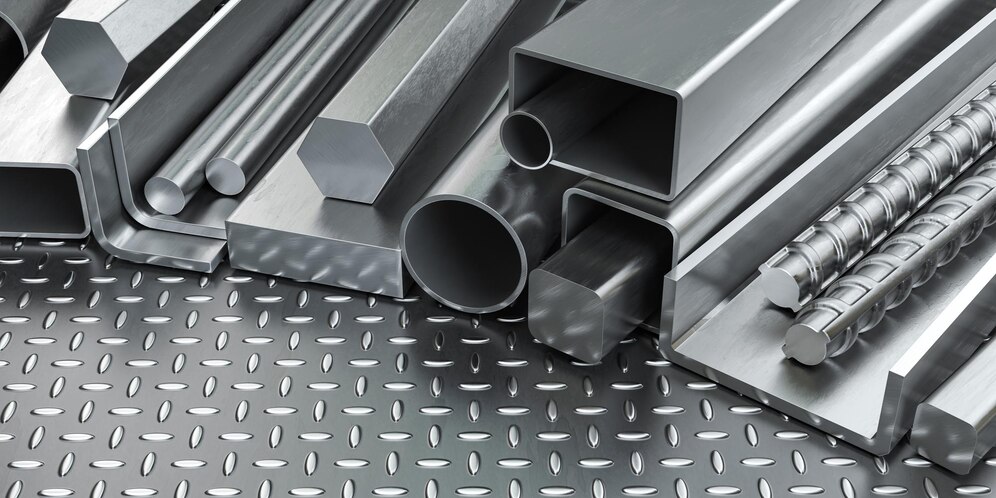

2. Product Quality and Variety:

Evaluate the quality of steel plates offered by the stockist. Ensure that they source their materials from reputable manufacturers known for producing durable and high-performance steel. Furthermore, choose a stockist that offers a wide variety of steel plates in different grades, sizes, and specifications to meet the unique requirements of your project.

3. Technical Expertise and Support:

An experienced stockist with technical expertise can provide valuable insights and assistance throughout your project. Opt for a supplier that employs knowledgeable staff capable of offering guidance on material selection, fabrication techniques, and other relevant aspects. Additionally, inquire about their after-sales support services, including assistance with material testing, certification, and troubleshooting.

4. Inventory Management and Availability:

Timely availability of steel plates is crucial to keep your project on schedule. Choose a stockist with efficient inventory management systems and ample stock levels to ensure prompt delivery whenever needed. Additionally, inquire about their lead times, order processing procedures, and ability to accommodate urgent or custom orders.

5. Price Competitiveness and Transparency:

While cost is a significant factor, it shouldn’t be the sole determinant when choosing a steel plate stockist. Compare prices from different suppliers to ensure competitive rates without compromising on quality. Additionally, look for transparency in pricing, including clear breakdowns of costs, potential surcharges, and any applicable discounts or promotions.

6. Environmental and Ethical Considerations:

In today’s environmentally conscious world, consider the sustainability practices and ethical standards of the steel plate stockist. Choose suppliers committed to responsible sourcing, waste reduction, and environmental stewardship. Additionally, inquire about their adherence to labor and safety regulations to ensure ethical practices throughout their operations.

7. Location and Logistics:

The proximity of the steel plates stockist to your project site can impact transportation costs, lead times, and overall convenience. Evaluate the supplier’s geographical location and logistics capabilities to determine their ability to efficiently deliver materials to your location. Additionally, consider factors such as shipping options, packaging, and handling procedures.

Conclusion:

Choosing the right steel plate stockist is a critical decision that can significantly impact the success of your project. By considering factors such as reputation, product quality, technical expertise, availability, pricing, sustainability, and logistics, you can make an informed choice that meets your project requirements and objectives. Remember to conduct thorough research, seek recommendations, and communicate openly with potential suppliers to ensure a mutually beneficial partnership. With the right stockist by your side, you can proceed with confidence, knowing that your project is supported by top-quality materials and reliable service.