India’s manufacturing sector has always been an essential driver of its economy, and the fastener industry is a significant contributor to this growth. Fasteners—such as bolts, screws, nuts, and washers—may seem small and simple, but they are the unsung heroes that hold together everything from household appliances to large infrastructure projects, machinery, and automobiles.

The fastener manufacturing industry in India has grown rapidly over the years. As the demand for high-quality, reliable, and cost-effective fasteners continues to rise globally, India has emerged as a competitive player in the international market. Let’s explore how Indian fastener manufacturers are achieving excellence in quality and service, and how they are positioning themselves in the global market.

The Role of Fasteners in Industries

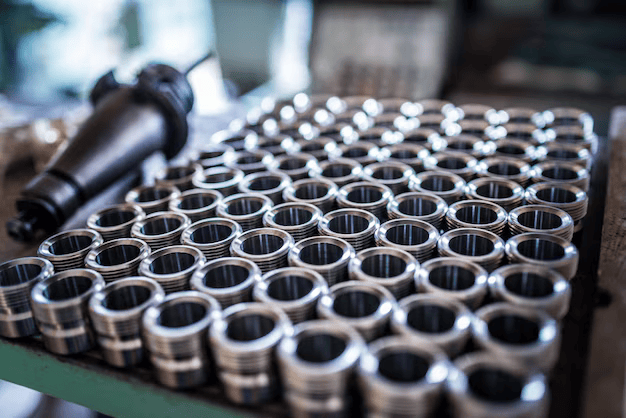

Fasteners are found in almost every industry. Whether it’s for the automotive, aerospace, construction, or electronics sector, these components are essential in ensuring products function safely and efficiently. Without fasteners, there would be no way to hold parts together in a reliable and secure manner.

In India, fastener manufacturing has become a thriving industry, thanks to the country’s large manufacturing base, skilled workforce, and cost-effective production techniques. These components are indispensable in sectors such as:

- Automotive: Fasteners are integral to assembling vehicles, from securing engine components to body panels.

- Construction: Buildings, bridges, and infrastructure projects require fasteners to hold structural elements and materials together.

- Aerospace and Defense: The aerospace industry demands high-precision fasteners that can withstand extreme conditions, such as high pressure, temperature, and stress.

- Electronics: In electronics, tiny screws, bolts, and clips secure circuit boards, display panels, and other parts in devices like smartphones, computers, and household appliances.

The importance of these fasteners cannot be overstated. Their strength, durability, and reliability are essential in keeping these industries running smoothly.

Key Drivers Behind India’s Fastener Industry Growth

Several factors have contributed to the rapid growth and success of fastener manufacturers in India:

1. Quality Manufacturing

Indian fastener manufacturers are increasingly meeting and exceeding international quality standards, such as ISO 9001 certification. This focus on quality ensures that products are durable, reliable, and perform well under various conditions. To meet global standards, manufacturers often invest in advanced machinery and modern manufacturing techniques that guarantee precision and consistency.

2. Skilled Workforce

India has a vast pool of skilled engineers and technicians who specialize in metallurgy, design, and manufacturing. This knowledge base has been pivotal in helping manufacturers develop fasteners that meet complex specifications for various industries. Many companies also provide ongoing training programs to ensure workers remain updated on the latest technological advancements.

3. Cost-Effectiveness

One of the key advantages of Indian fastener manufacturers is their ability to produce high-quality products at competitive prices. The relatively lower cost of labor, along with efficient supply chains, allows companies to keep production costs low without sacrificing quality. This makes Indian fasteners an attractive option for both domestic and international buyers looking for value without compromising on performance.

4. Technological Advancements

As industries demand more precision and higher quality products, Indian fastener manufacturers are embracing cutting-edge technology. Advanced Computer Numerical Control (CNC) machines, automation, and robotic systems help improve production efficiency and accuracy, while reducing human error. This technological progress allows manufacturers to stay competitive in a global market.

5. Robust Infrastructure

The fastener industry benefits from India’s growing infrastructure. Investments in logistics, transport networks, and industrial hubs in states like Gujarat, Maharashtra, and Tamil Nadu have enhanced the efficiency of fastener manufacturers. These improvements allow for smoother operations, faster deliveries, and more streamlined production processes.

6. Diverse Product Range

The fastener industry in India is incredibly versatile, offering a vast range of products to meet different industry needs. Whether it’s standard fasteners or custom-made solutions, Indian manufacturers cater to everything from high-strength automotive fasteners to fine screws used in electronics. The ability to meet specific requirements makes Indian manufacturers a preferred choice for buyers around the world.

7. Focus on Sustainability

As sustainability becomes a significant concern for manufacturers globally, Indian fastener companies are adopting eco-friendly practices. From sourcing recyclable raw materials to reducing energy consumption in production, many fastener manufacturers are committed to minimizing their environmental impact. This focus on sustainability adds another layer of appeal to Indian fasteners, particularly for environmentally-conscious companies.

See Also Ultimate Guide to Fastener Manufacturers in India: Choosing the Right Partner for Your Needs

Challenges Faced by Fastener Manufacturers in India

While the fastener manufacturing sector in India has flourished, it does face a few challenges that need attention.

1. Raw Material Costs

The cost of raw materials such as steel, brass, and aluminum is subject to fluctuations. This can sometimes affect production costs and profit margins. Manufacturers need to maintain strong relationships with suppliers and have contingency plans in place to mitigate this challenge.

2. Intense Competition

The global fastener market is highly competitive, and Indian manufacturers face pressure from suppliers in countries like China, which dominate the global market. To remain competitive, Indian manufacturers must maintain high-quality standards and innovate to meet the evolving needs of the industries they serve.

3. Technological Adaptation

While many Indian manufacturers have embraced advanced technology, some smaller players struggle with upgrading their facilities due to budget constraints. To remain competitive, manufacturers must invest in automation and modern manufacturing techniques, particularly to reduce labor costs and improve quality.

4. Export and Regulatory Challenges

Although Indian fasteners are in demand across the globe, manufacturers sometimes face challenges in complying with different international regulations and certification requirements. Ensuring that products meet the specific standards of foreign markets, while navigating complex customs procedures, can be time-consuming and costly.

Conclusion

The fastener manufacturing industry in India has seen remarkable growth due to its ability to produce high-quality products, skilled labor, and competitive pricing. As industries continue to expand and evolve, the demand for reliable and durable fasteners will continue to rise. Indian manufacturers are well-positioned to meet this demand, not only within the country but also on the global stage.

However, as competition increases and markets become more demanding, Indian fastener manufacturers must continue to innovate, adopt new technologies, and ensure that their products remain of the highest quality.

To help buyers find reliable suppliers, platforms like Enggpro provide a comprehensive list of fastener manufacturers and suppliers in India. These platforms allow customers to connect with trusted manufacturers who can meet their specific needs and provide high-quality products. Let’s take a closer look at what makes Enggpro a valuable resource for sourcing fasteners.

List of Fasteners Manufacturers and Suppliers from Enggpro

Enggpro is a leading online platform connecting buyers and suppliers across industries, offering a wide selection of fastener manufacturers and suppliers from India. Some of the standout features of Enggpro’s listed fastener manufacturers include:

- Wide Product Range: Enggpro suppliers offer everything from standard fasteners like bolts, nuts, and screws to custom fastener solutions for specialized applications.

- Global Reach: Suppliers cater to both domestic and international clients, ensuring fast delivery times and competitive pricing for global projects.

- Quality Assurance: Manufacturers listed on Enggpro are committed to maintaining top-tier quality and often comply with internationally recognized certifications like ISO 9001.

- Customization Options: For industries with specific requirements, Enggpro suppliers offer customization services, ensuring products meet unique specifications.

- State-of-the-Art Facilities: The manufacturers are equipped with the latest manufacturing technology, which ensures precision, durability, and fast turnaround times.

- Commitment to Sustainability: Many suppliers focus on green manufacturing processes, ensuring that their operations have minimal environmental impact.

Enggpro simplifies the process of sourcing high-quality fasteners from trusted manufacturers. Whether you’re in construction, automotive, aerospace, or electronics, Enggpro connects you with suppliers that can meet your exact requirements.

In conclusion, the fastener manufacturing industry in India is booming, and with its focus on quality, innovation, and cost-effectiveness, it continues to be a significant player on the global stage. Platforms like Enggpro make it easy to connect with reliable fastener manufacturers, ensuring that industries across the world have access to the high-quality products they need.