Gate valves and ball valves are two of the most commonly used valves in various industries for controlling the flow of liquids and gases. While both serve the primary function of flow regulation, they differ significantly in design, operation, advantages, and suitable applications. Understanding these differences is crucial for selecting the appropriate valve for your specific needs.

Gate Valves

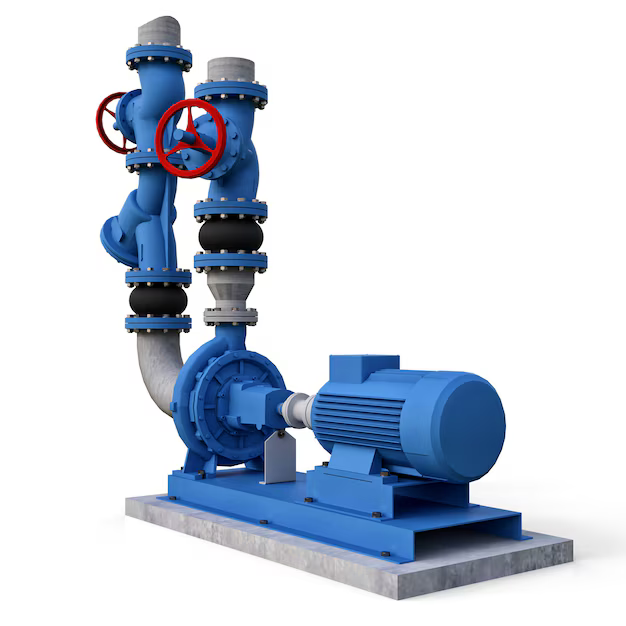

Gate valves operate by lifting a gate (a solid disk) out of the path of the fluid. They are primarily designed for fully open or fully closed service. When the valve is fully open, the gate is entirely drawn up into the valve bonnet, leaving the passageway clear for fluid flow. Conversely, when closed, the gate seats into the valve body, effectively stopping the flow.

Design and Operation

The key components of a gate valve include the body, bonnet, gate, stem, and actuator (which can be a handwheel or motor). Turning the actuator moves the stem, which in turn raises or lowers the gate to open or close the valve. This multi-turn operation means that gate valves require multiple turns of the actuator to transition from open to closed positions, allowing for gradual changes in flow.

Advantages of Gate Valves

- Low Fluid Resistance: When fully open, gate valves offer minimal resistance to flow because the gate is entirely out of the fluid’s path, resulting in a straight-through flow with negligible pressure drop.

- Superior Sealing Performance: Gate valves provide excellent sealing capabilities, making them suitable for applications requiring tight shut-off.

- Bidirectional Flow: They allow flow in both directions and are not restricted to a single flow direction, offering flexibility in system design.

- Versatility: Gate valves are compatible with various media, including steam, oil, and other fluids. They can also handle media with granular materials and high viscosity, making them suitable for a wide range of applications.

Disadvantages of Gate Valves

- Slower Operation: Due to their multi-turn design, gate valves take longer to open or close compared to quarter-turn valves like ball valves.

- Prone to Jamming: In applications involving slurries or viscous fluids, particles can accumulate in the tracks, potentially causing the gate to jam.

- Maintenance Challenges: Over time, the stem may corrode, and the seating surfaces can wear out, leading to potential leakage and requiring maintenance.

Common Applications

Gate valves are widely used in applications where a straight-line flow of fluid and minimum restriction is desired. They are suitable for high-pressure and high-temperature environments and are commonly found in:

- Water Supply Systems: Used to isolate specific sections of the system.

- Oil and Gas Industry: Employed in pipelines to control the flow of crude oil and natural gas.

- Power Plants: Utilized in various systems to control steam and feedwater flow.

See Also Top Valves Manufacturers in India You Need to Know About

Ball Valves

Ball valves utilize a spherical ball with a hole (bore) through its center to control fluid flow. Rotating the ball a quarter turn (90 degrees) allows the valve to open or close, providing quick and efficient flow control.

Design and Operation

The primary components of a ball valve include the body, ball, stem, seats, and actuator. When the actuator turns the stem, the ball rotates to align the bore with the flow path (open position) or perpendicular to it (closed position). This quarter-turn operation enables rapid opening and closing.

Advantages of Ball Valves

- Quick Operation: The quarter-turn mechanism allows for rapid opening and closing, making ball valves ideal for applications requiring immediate shut-off.

- Tight Sealing with Low Torque: Ball valves provide a tight seal with minimal torque, ensuring reliable shut-off even after prolonged periods of use.

- Durability: They are less prone to wear and corrosion, offering a longer service life with minimal maintenance.

- Versatility: Available in various configurations, including multi-port designs, ball valves can manage complex flow control scenarios.

Disadvantages of Ball Valves

- Potential for Water Hammer: The rapid operation of ball valves can cause water hammer, a pressure surge that can damage the system.

- Not Ideal for Throttling: Partially open ball valves can cause erosion of the seats and the ball due to high-velocity flow, leading to leakage.

- Size Limitations: Ball valves are typically not practical for large-diameter pipelines due to the size and weight of the ball.

Common Applications

Ball valves are suitable for applications requiring quick shut-off and are commonly used in:

- Residential Plumbing: Used in water supply lines for appliances and fixtures.

- Chemical and Petrochemical Industries: Applied in systems handling corrosive fluids.

- Manufacturing Processes: Utilized in various process systems for fluid control.

See Also Valve Manufacturers in India: A Comprehensive Overview

Key Differences Between Gate Valves and Ball Valves

- Operation Mechanism: Gate valves require multiple turns to open or close, providing gradual flow control, whereas ball valves operate with a simple quarter-turn for quick action.

- Flow Control: Gate valves are suitable for applications where flow needs to be regulated slowly, while ball valves are ideal for applications requiring rapid shut-off.

- Sealing Capability: Ball valves offer a tighter seal compared to gate valves, making them preferable in applications where leakage cannot be tolerated.

- Durability and Maintenance: Ball valves are generally more durable and require less maintenance due to their simple design and resistance to wear.

- Cost: Gate valves are typically less expensive than ball valves of the same size and specifications, making them a more budget-friendly option for larger pipelines. However, ball valves tend to have a longer service life and lower maintenance costs, which can make them more cost-effective in the long run.

Choosing the Right Valve for Your Needs

When selecting between gate valves and ball valves, consider the following factors:

1. Application Type

- If you need a valve for ON/OFF applications with minimal pressure drop, a gate valve is a good choice.

- If you require fast and reliable shut-off, a ball valve is more suitable.

2. Pressure and Temperature Conditions

- Gate valves are better suited for high-pressure, high-temperature applications, such as in steam and power plants.

- Ball valves perform well in moderate pressure applications, especially in fluid systems that require quick shut-off.

3. Frequency of Operation

- Gate valves are not ideal for frequent opening and closing due to wear on the gate and seat.

- Ball valves, with their quarter-turn design, can handle frequent operation with minimal wear.

4. Space Constraints

- Ball valves are more compact and lightweight, making them suitable for confined spaces.

- Gate valves require more installation space due to their linear movement mechanism.

5. Fluid Type

- Ball valves are excellent for clean liquids and gases, but they may not perform well with slurries or thick fluids.

- Gate valves can handle thicker fluids and slurries but may be prone to clogging if debris gets trapped in the gate.

Conclusion

Gate valves and ball valves each have their unique strengths and limitations. Gate valves provide reliable sealing and are ideal for high-pressure applications, while ball valves offer quick operation and durability. The choice between the two depends on the specific requirements of your system, including operating conditions, maintenance needs, and cost considerations.

For industries such as oil and gas, chemical processing, water treatment, and power generation, selecting the right valve can significantly impact efficiency, safety, and long-term operational costs.

List of Valve Manufacturers in India from Enggpro

Enggpro is a leading B2B platform that connects buyers with trusted valve manufacturers in India. Here are some of the top valve manufacturers listed on Enggpro along with their key features:

1. L&T Valves

Features:

- Specializes in high-performance industrial valves

- Offers gate, globe, check, and ball valves

- Used in oil & gas, power, and water industries

- ISO and API certified for quality assurance

2. Kirloskar Brothers Limited

Features:

- Provides a wide range of industrial and utility valves

- Expertise in butterfly, gate, and check valves

- Strong presence in water supply and power sectors

- Advanced R&D facilities for innovative solutions

3. Audco Valves

Features:

- Known for reliability in high-pressure applications

- Offers high-performance ball, plug, and butterfly valves

- Widely used in petrochemical and refining industries

- Durable designs for harsh operating conditions

4. BHEL (Bharat Heavy Electricals Limited)

Features:

- Manufactures industrial and control valves

- Preferred supplier for power plants and heavy industries

- Produces safety and pressure relief valves

- Strong focus on energy-efficient valve designs

5. Niton Valve Industries

Features:

- Specializes in high-precision valves for critical applications

- Provides custom-engineered solutions for oil & gas, chemical, and marine industries

- Certified for API, ISO, and CE standards

- Offers corrosion-resistant materials for longevity

6. Hawa Valves

Features:

- Offers ball, gate, globe, and check valves

- Expertise in handling severe service applications

- Supplies valves for LNG, offshore, and refining industries

- Strong global presence with high-quality manufacturing standards

7. Amco Valves

Features:

- Manufacturer of industrial and custom-made valves

- Offers a wide range of pressure control valves

- Preferred supplier for nuclear, defense, and aerospace applications

- Ensures high safety and performance standards

Enggpro provides a seamless platform to explore and connect with these valve manufacturers, ensuring you find the right product for your needs. Whether you require gate valves for high-pressure environments or ball valves for quick shut-off applications, Enggpro helps you source the best quality valves from reputed Indian manufacturers.