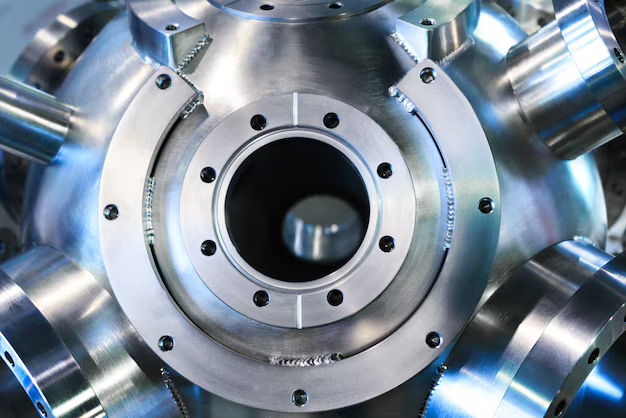

Selecting the appropriate flange for your industrial application is crucial to ensure the efficiency, safety, and longevity of your piping systems. Flanges serve as vital components that connect pipes, valves, pumps, and other equipment, facilitating the flow of fluids and gases. This comprehensive guide will walk you through the essential considerations for choosing the right flange and provide a curated list of reputable flange manufacturers in India.

Understanding Flanges

A flange is a mechanical device used to connect pipes, valves, pumps, and other equipment to form a piping system. It provides a reliable means of assembling and disassembling components, allowing for maintenance, inspection, and modification. Flanges are typically joined by bolting and sealed using gaskets to prevent leakage.

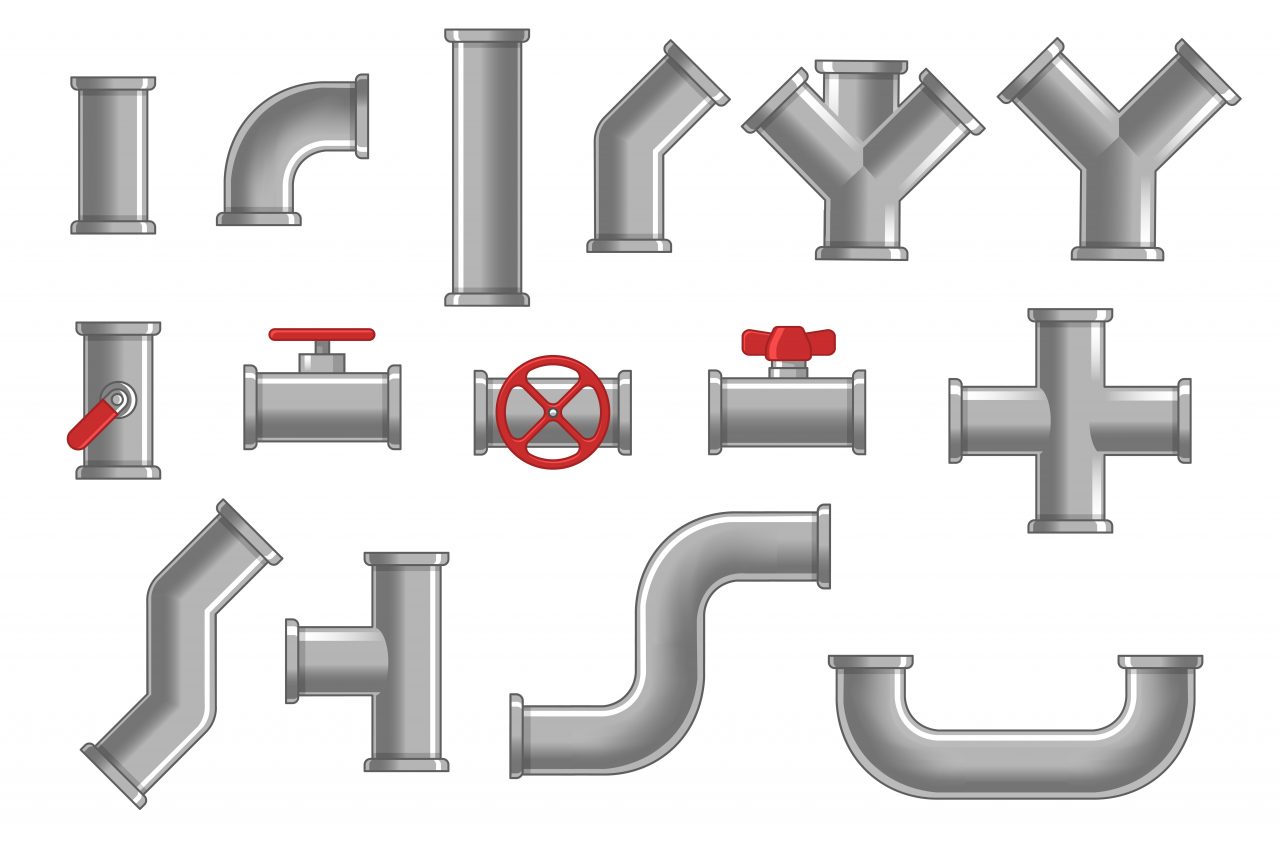

Types of Flanges

Flanges come in various types, each designed to meet specific requirements based on factors such as pressure, temperature, and application. Some common types include:

-

Weld Neck Flanges: Featuring a long tapered hub, weld neck flanges are ideal for high-pressure and high-temperature applications. The hub provides reinforcement, reducing stress concentration at the base of the flange.

-

Slip-On Flanges: These flanges have a slightly larger diameter than the pipe, allowing them to slip over the pipe before welding. They are commonly used in low-pressure and non-critical applications due to their ease of installation.

-

Socket Weld Flanges: Designed with a recessed area (socket) into which the pipe end fits, socket weld flanges are secured by fillet welding. They are suitable for small-diameter, high-pressure pipelines.

-

Blind Flanges: Used to seal the end of a piping system or vessel opening, blind flanges do not have a bore. They are essential for systems that require future expansion or inspection.

-

Lap Joint Flanges: Consisting of two components—a stub end and a loose backing flange—lap joint flanges are useful in systems requiring frequent disassembly for inspection or maintenance.

-

Threaded Flanges: These flanges have internal threads that match the external threads of the pipe, allowing for assembly without welding. They are suitable for low-pressure applications and systems where welding is hazardous.

-

Orifice Flanges: Incorporating a tapped hole for measuring flow rates, orifice flanges are used in conjunction with orifice plates or flow nozzles in metering systems.

See Also Flanges Manufacturer in India: Your Ultimate Resource for Quality Products

Key Considerations for Selecting the Right Flange

Choosing the appropriate flange involves evaluating several critical factors:

1. Material Compatibility

The flange material must be compatible with the fluid or gas being transported to prevent corrosion, contamination, or degradation. Common materials include:

-

Carbon Steel: Suitable for high-temperature and high-pressure applications but susceptible to corrosion in certain environments.

-

Stainless Steel: Offers excellent corrosion resistance and is ideal for sanitary applications or corrosive environments.

-

Alloy Steel: Used for specific applications requiring enhanced mechanical properties or resistance to particular chemicals.

-

Non-Ferrous Metals: Materials like aluminum, copper, or nickel alloys are chosen for specialized applications based on their unique properties.

2. Pressure and Temperature Ratings

Flanges are designed to withstand specific pressure and temperature ranges. It’s essential to select a flange that meets or exceeds the operational conditions of your system. Flange standards, such as ASME B16.5, provide classifications (e.g., Class 150, 300, 600) that denote pressure ratings.

3. Size and Thickness

The flange’s dimensions, including its nominal pipe size (NPS) and schedule (wall thickness), must match the piping system to ensure a proper fit and maintain system integrity.

4. Facing Type

The flange facing determines the type of gasket to be used and affects the sealing performance. Common facing types include:

-

Raised Face (RF): Features a raised surface and is widely used in various applications.

-

Flat Face (FF): The entire face is flat, suitable for mating with flat surfaces, often in low-pressure applications.

-

Ring Type Joint (RTJ): Incorporates a groove for a metal ring gasket, providing a high-integrity seal for high-pressure and high-temperature services.

5. Application and Environment

Consider the specific application and environmental conditions, such as exposure to corrosive substances, extreme temperatures, or hygienic requirements, to select a flange that will perform reliably under those conditions.

See Also Top Flanges Manufacturers in India: A Comprehensive Guide for Industry Professionals

List of Flange Manufacturers in India

India boasts a robust industrial sector with numerous reputable flange manufacturers. Here is a curated list of some prominent companies:

1. Kirloskar Group

Established in 1888, the Kirloskar Group is a renowned Indian conglomerate headquartered in Pune. The group specializes in manufacturing pumps, engines, compressors, chillers, valves, and more.

Features:

-

Diverse Product Range: Offers a wide array of industrial products, including high-quality flanges suitable for various applications.

-

Global Presence: Exports to over 70 countries, ensuring international standards and quality.

-

Innovation and Quality: Known for pioneering efforts in engineering and maintaining high-quality manufacturing practices.

2. Hinduja Foundries

Part of the Hinduja Group, Hinduja Foundries is India’s largest casting manufacturer, established in 1959. The company operates facilities in Chennai and Hyderabad, producing a wide range of castings, including those used in flanges.

Features:

-

Extensive Experience: Over six decades of expertise in casting manufacturing.

-

Advanced Facilities: State-of-the-art manufacturing plants equipped with modern technology.

-

Customized Solutions: Ability to produce tailored castings to meet specific industrial requirements.

3. ISGEC Heavy Engineering Ltd.

Founded in 1933, ISGEC Heavy Engineering Ltd. is a prominent Indian company offering a range of engineering products, including process equipment, industrial boilers, and more.