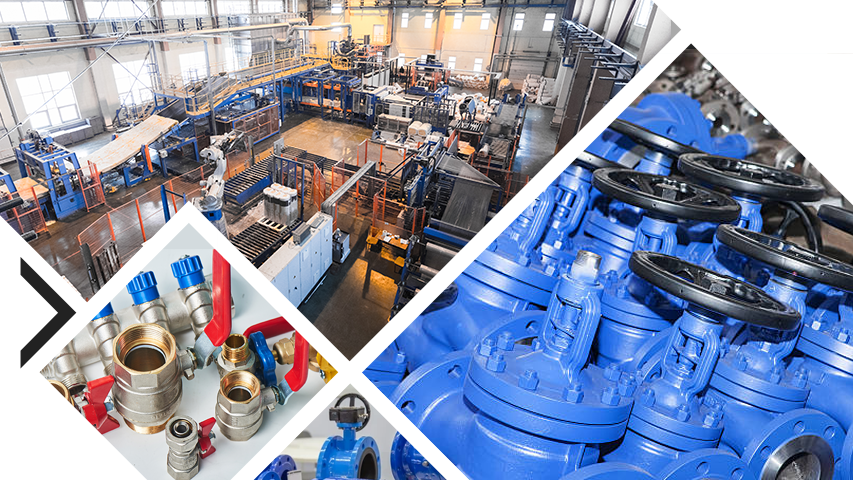

Valves are mechanical devices helpful in controlling and reducing the flow of liquids, gases, oil, vapors. Valves are valuable in various types of pipe systems to handle pressure. Values are extremely helpful in all manufacturing and technological companies. Industrial Valves manufacturers are in tremendous demand as they play a crucial role in all types of industrial, commercial, and even residential purposes. There are numerous types of valves available in the market depending on the requirements of the companies.

There are several types of valves like

1. Butterfly Valves:-

The butterfly valve is a quarter-turn valve, which helps to regulate the flow of fluid through the pipe. There is a level of control that helps in controlling the flow of fluid. There is a complete flow of fluid in the channel, which includes the set amount of efficiency.Valves manufacturers in India build butterfly valves with tight closure with the help of high-temperature ratings and the latest polymers.

There are various elements in butterfly valves like a metallic disc or butterfly disc, an outer body/casing, an actuator, and a positioning plate. There is the creation of a strong seal with the help of packaging. These seals help for the protection of the stem by surrounding the stem. The disc is available at the top of the rod, due to which it restricts fluid flow when the valve is closed. The movement of the disc depends on the opening and closing of the valve.

Butterfly Valves Advantages

- The weight of the butterfly valve is very light, and the body is the wafer-form body.

- The mass of the butterfly valve is less, due to which it can come into use in many applications.

2. Ball Valves:-

The Ball Valves came into existence in 1950, and after that, it has gained popularity. The ball valve contains a ball having holes in it. After the alignment of the pipe and pocket, then water or other fluids can pass through it.

There are different types of ball valves like flanged, hydraulic, standard, vented ball valves. The creation of a ball valve takes place with the help of a valve stem, a valve seat, O-rings, and valve housing.

Ball Valves Advantages

- The sealing available in the Ball valve is perfect as it protects both sides.

- The flow resistance in the Ball Valve is very economical.

3. Globe Valves

The usage of the globe valve is for regulation, stopping, and starting liquid or fluid flow. The disc available on the globe valve can be detached/removed depending on the requirement. The movement of the disc is at a 90-degree angle at the time of opening and closing of the valve. In Globe Valve, there is angular space between the disc and the seat ring. The control of fluid takes place with the help of Globe Valve.

Globe Valve Advantages

- There is low friction between the valve flap and sealing surface, due to which Globe valves are wear-resistant.

- It is easy to maintain Globe Valve as there is only one sealing surface.

4. Gate Valves

With the help of a rectangular gate, Gate Valve stops the inflow and outflow of fluids. The structure of Gate Valve is wedge type, due to which it can restrict the flow of liquid. It takes the least space in the pipe. There are three components in Gate Valve like the bonnet, the body, and the trim.

The three components available in Gate Valve work in unison, due to which it provides the best result. Gate Valve takes 360 degrees to close and open the valve.

Gate valves Advantages

- The requirement of torque is less to open and close the valve.

- The design and structure of the Gate Valve are very modest.

5. Check Valves

The unidirectional valve is known as the check valve. These show that the passage of fluid takes place in one direction only. There are two openings in this check valve. The check valve is self-automated. At the time when flow reverses, the valve closes.

Check valve takes place in the pipeline, which can restrict the flow in the backward direction.

The check valve is very beneficial and has several applications in several industries.

Check Valves Advantages

- With the help of a check valve, it can decrease downtime.

- There is the least risk of valve failure by a check valve.

Conclusion:-

Numerous Industrial Valves manufacturers are providing high-quality Industrial Valves in extreme ranges. Manufacturing of valves includes design, material procurement, manufacturing, assembly, and testing of valves. Industrial Valves manufacturers help companies provide creative solutions and dependable results.

They manufacture, supply, and export our superior quality Industrial Valves to their clients and customers all over UAE and many other countries. Industrial Valves manufacturers make sure that valves deliver consistent high performance.