India’s manufacturing sector has witnessed unprecedented growth in recent years, positioning itself as a global hub for various industrial products, including valves. The country’s valve manufacturing industry is on an upward trajectory, driven by technological advancements, government support, and the increasing demand for infrastructure and industrial projects. From water treatment plants to oil and gas exploration, valves are critical components in numerous sectors, and Indian manufacturers are stepping up to meet the global demand.

This blog will explore the rise of valve manufacturers in India, highlighting the key innovations, industry insights, and future prospects for this growing sector.

Overview of the Valve Industry in India

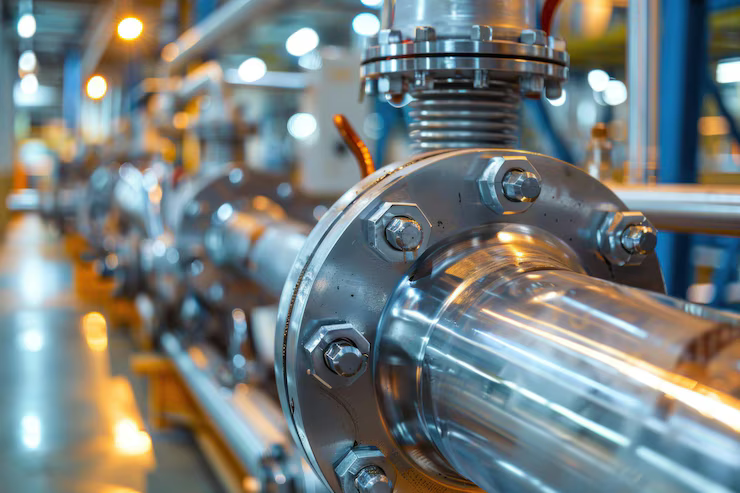

Valves are essential mechanical devices used to regulate the flow of fluids (gases, liquids, or slurries) in industrial applications. They are widely employed in various industries such as oil and gas, power generation, chemical processing, water treatment, and pharmaceuticals. The Indian valve industry has evolved significantly, with manufacturers catering to both domestic and international markets.

India’s valve manufacturing industry is characterized by a wide range of products, including gate valves, globe valves, ball valves, butterfly valves, and pressure-relief valves. The industry caters to a diverse range of sectors, and the demand for valves is primarily driven by rapid industrialization, urbanization, and infrastructural development.

Factors Driving the Growth of Valve Manufacturers in India

Several factors are contributing to the growth of the valve manufacturing industry in India, making it one of the fastest-growing sectors in the engineering domain:

1. Government Initiatives and Support

The Indian government has launched various initiatives like “Make in India” and “Aatmanirbhar Bharat” to promote domestic manufacturing. These initiatives encourage local manufacturers to invest in research and development (R&D), adopt modern technologies, and enhance their production capabilities. Furthermore, the government’s focus on infrastructure development, including smart cities and industrial corridors, has created a high demand for valves.

2. Growing Industrial Sectors

India’s expanding industrial base, especially in sectors like oil and gas, power generation, chemicals, and pharmaceuticals, has significantly increased the demand for high-quality valves. In particular, the oil and gas industry has been a major consumer of valves due to the need for precise flow control in pipelines and refineries. The power generation sector, driven by renewable energy projects and coal-fired plants, also requires advanced valves for efficient operations.

3. Global Demand for Indian Valves

India’s valve manufacturing sector is gaining global recognition for producing high-quality, cost-effective products. Indian valve manufacturers have established strong export markets in countries like the United States, the United Arab Emirates, Germany, and Saudi Arabia. The competitive pricing of Indian valves, combined with adherence to international standards, has made them a preferred choice for many global industries.

4. Technological Advancements

Indian valve manufacturers are increasingly investing in cutting-edge technologies to stay competitive in the global market. Automation, digitalization, and the use of advanced materials are becoming prevalent in valve manufacturing processes. Modern valve systems are equipped with sensors, actuators, and control systems that enhance performance and efficiency. These advancements are making Indian valves more reliable, durable, and efficient, catering to the evolving needs of various industries.

5. Focus on Quality and Certifications

To meet international standards and gain a competitive edge in global markets, Indian valve manufacturers are prioritizing quality and obtaining necessary certifications. Many manufacturers in India are ISO-certified, and they adhere to stringent quality control processes. This focus on quality has enhanced the reputation of Indian-made valves, contributing to the industry’s growth and global acceptance.

See Also Top Valves Manufacturers in India You Need to Know About

Innovations in the Indian Valve Manufacturing Sector

As the valve manufacturing industry in India continues to grow, innovation has become a key differentiator. Indian manufacturers are embracing new technologies and adopting innovative practices to enhance their product offerings.

1. Smart Valves and Automation

With the rise of Industry 4.0, automation and smart technologies are revolutionizing valve manufacturing in India. Smart valves, equipped with sensors and actuators, allow for remote monitoring and control, making them ideal for critical applications in industries like oil and gas, water treatment, and power generation. These valves can be integrated into larger industrial systems, enabling real-time data collection and predictive maintenance, which reduces downtime and increases operational efficiency.

2. Advanced Materials for Valves

Traditional valve materials like cast iron and stainless steel are being supplemented by advanced materials that offer better resistance to corrosion, high pressure, and extreme temperatures. Indian manufacturers are increasingly using materials such as titanium, Hastelloy, and duplex stainless steel in valve production. These materials not only extend the lifespan of valves but also improve their performance in challenging environments.

3. Customized Valves for Specialized Applications

Customization has become a key trend in the valve manufacturing industry. Indian manufacturers are offering tailored solutions for specific industries, such as petrochemicals, pharmaceuticals, and food processing. Customization allows manufacturers to design valves that meet the unique requirements of each industry, ensuring optimal performance and safety.

4. Sustainability and Energy Efficiency

Sustainability is becoming a critical factor in valve design and production. Indian valve manufacturers are focusing on energy-efficient designs that reduce energy consumption and environmental impact. Valves that minimize leakage, reduce pressure loss, and optimize flow control are gaining popularity, especially in industries that prioritize sustainability, such as water treatment and renewable energy.

Key Players in the Indian Valve Manufacturing Industry

The Indian valve manufacturing industry is home to several leading players that have established themselves both domestically and internationally. These companies have made significant contributions to the growth of the industry and have set benchmarks for quality and innovation.

1. L&T Valves

L&T Valves is one of the largest valve manufacturers in India, with a global presence in over 40 countries. The company offers a wide range of valves, including gate valves, globe valves, ball valves, and butterfly valves, catering to industries such as oil and gas, power, water, and chemicals. L&T Valves is known for its high-quality products, cutting-edge technology, and customer-centric approach.

2. KSB Limited

KSB Limited is a leading manufacturer of industrial valves and pumps, with a strong focus on innovation and sustainability. The company offers a diverse portfolio of valves for applications in water treatment, power generation, and chemicals. KSB’s commitment to quality and innovation has made it a trusted name in both domestic and international markets.

3. BHEL (Bharat Heavy Electricals Limited)

BHEL is a prominent player in India’s valve manufacturing industry, specializing in valves for power generation and industrial applications. BHEL’s valves are known for their reliability, durability, and performance in demanding environments. The company’s expertise in engineering and manufacturing has helped it maintain a strong foothold in the valve industry.

4. Audco India Limited

Audco India Limited is a joint venture between L&T and Flowserve Corporation, offering a wide range of valves for various industries. The company is known for its high-performance valves, particularly in the oil and gas sector. Audco’s products are designed to meet the stringent requirements of critical applications, making them a preferred choice for global clients.

5. CRI Valves

CRI Valves is a well-established manufacturer of industrial valves in India, with a focus on providing solutions for water, sewage, and power sectors. The company’s innovative valve designs and commitment to quality have earned it a strong reputation in the domestic market. CRI Valves is continuously expanding its product offerings to cater to the evolving needs of the industry.

Challenges Facing the Valve Manufacturing Industry in India

While the valve manufacturing industry in India is experiencing significant growth, it is not without challenges. Some of the key challenges include:

- Competition from Global Players: Indian manufacturers face stiff competition from global valve manufacturers, particularly from countries like China, Germany, and the United States. To remain competitive, Indian companies need to continue investing in R&D, innovation, and quality improvements.

- Fluctuating Raw Material Prices: The cost of raw materials, especially metals like stainless steel and titanium, can be volatile. Fluctuating prices can impact the profitability of valve manufacturers and pose challenges in maintaining cost-effective production.

- Skilled Labor Shortage: The valve manufacturing industry requires a skilled workforce for production, assembly, and testing. A shortage of skilled labor can hinder the industry’s ability to scale up and meet increasing demand.

See Also The Ultimate Guide to Understanding Different Types of Valves

Future Outlook for the Valve Manufacturing Industry in India

The future of the valve manufacturing industry in India looks promising, with several growth opportunities on the horizon. The increasing demand for infrastructure development, coupled with the rise of smart cities and renewable energy projects, will continue to drive the need for advanced valve solutions. Furthermore, India’s strong export potential and growing reputation as a global manufacturing hub will ensure the industry’s sustained growth in the coming years.

Conclusion

India’s valve manufacturing industry has come a long way, driven by technological innovations, government support, and the growing demand from key industrial sectors. As Indian manufacturers continue to adopt advanced technologies and focus on quality, the industry is well-positioned to meet both domestic and global demand for high-performance valves.

If you’re looking for reliable valve manufacturers in India, Enggpro offers a comprehensive B2B marketplace where you can find a wide range of engineering products and services. Visit Enggpro to explore top valve manufacturers in India and meet your industrial needs.