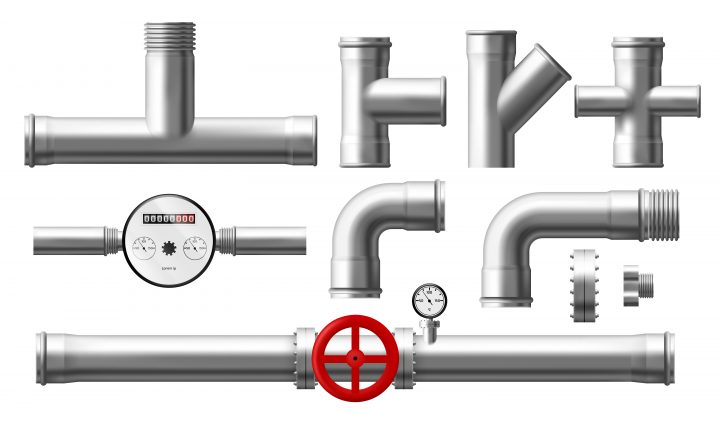

India’s pipe fittings manufacturing industry is undergoing a significant transformation as it moves into 2024. Driven by technological advancements and evolving market demands, the industry is poised for substantial growth. In this blog, we will explore the latest innovations and trends shaping the future of pipe fittings manufacturing in India, highlighting the key factors that will influence its trajectory.

1. Technological Advancements

One of the most significant drivers of change in pipe fittings manufacturing is the rapid advancement in technology. In 2024, manufacturers in India are increasingly adopting cutting-edge technologies to enhance production efficiency and product quality.

-

a. Automation and Robotics

Automation is revolutionizing the manufacturing process by increasing precision and reducing labor costs. Robotic systems are now being employed for tasks such as welding, assembly, and quality control, ensuring consistent and high-quality output. These advancements are not only improving production speed but also enhancing safety in the manufacturing environment.

-

b. 3D Printing

The use of 3D printing technology is becoming more prevalent in the industry. It allows for rapid prototyping and the production of complex pipe fittings with intricate designs. This technology is particularly useful for creating custom fittings and reducing lead times for new product development.

-

c. Smart Manufacturing

The integration of the Internet of Things (IoT) in manufacturing processes is enabling real-time monitoring and data collection. Smart sensors and connected devices provide valuable insights into equipment performance, helping manufacturers predict maintenance needs and minimize downtime.

2. Sustainability and Environmental Concerns

Sustainability is becoming a critical focus for the pipe fittings manufacturing industry. As environmental regulations become stricter, manufacturers are adopting practices that minimize their ecological footprint.

-

a. Eco-Friendly Materials

There is a growing trend towards using sustainable and eco-friendly materials in pipe fittings. Manufacturers are exploring alternatives to traditional materials, such as recycled plastics and low-carbon steel, to reduce the environmental impact of their products.

-

b. Energy Efficiency

Energy-efficient manufacturing processes are gaining traction. Companies are investing in technologies that reduce energy consumption during production, such as advanced heating systems and energy recovery solutions. These measures not only lower operational costs but also contribute to a greener manufacturing environment.

-

c. Waste Reduction

Reducing waste is a key priority for manufacturers. Techniques such as lean manufacturing and process optimization are being implemented to minimize material wastage and improve resource utilization.

3. Market Trends and Demands

The demand for pipe fittings in India is influenced by various market trends, which are shaping the industry’s future.

-

a. Infrastructure Development

India’s rapid infrastructure development, including urbanization projects and industrial expansion, is driving the demand for high-quality pipe fittings. The need for durable and reliable fittings in sectors such as construction, water supply, and oil and gas is fueling market growth.

-

b. Customization and Innovation

Customers are increasingly seeking customized solutions to meet specific requirements. Manufacturers are responding by offering a wider range of products with innovative designs and features. The ability to provide tailored solutions is becoming a competitive advantage in the market.

-

c. Export Opportunities

The Indian pipe fittings industry is also looking beyond domestic markets. With growing export opportunities, manufacturers are focusing on meeting international standards and expanding their global presence. This shift is driving investment in quality improvement and certification processes.

4. Regulatory and Compliance Factors

Regulatory standards play a crucial role in shaping the pipe fittings manufacturing industry. Compliance with both domestic and international regulations is essential for market success.

-

a. Quality Standards

Adhering to quality standards is imperative for manufacturers to ensure product reliability and safety. Indian manufacturers are increasingly aligning their processes with international standards such as ISO and ASTM to enhance their credibility and competitiveness.

-

b. Environmental Regulations

Compliance with environmental regulations is becoming more stringent. Manufacturers are required to meet standards related to emissions, waste disposal, and resource usage. Staying updated with regulatory changes and adopting compliant practices is crucial for long-term sustainability.

-

c. Safety Regulations

Ensuring worker safety is a top priority. Manufacturers are investing in safety training, protective equipment, and compliance with occupational health and safety regulations to create a secure working environment.

5. Emerging Technologies and Future Prospects

As the industry looks ahead, several emerging technologies are expected to shape the future of pipe fittings manufacturing in India.

-

a. Artificial Intelligence (AI)

AI is set to revolutionize manufacturing processes by enabling predictive maintenance, quality control, and process optimization. AI-driven analytics can provide valuable insights into production trends and help manufacturers make data-driven decisions.

-

b. Advanced Materials

Research into advanced materials such as composites and nanomaterials is opening new possibilities for pipe fittings. These materials offer enhanced properties such as higher strength, corrosion resistance, and reduced weight.

-

c. Digital Twins

Digital twin technology, which involves creating virtual replicas of physical assets, is gaining traction in the industry. By simulating manufacturing processes and product performance, digital twins can help optimize designs and predict potential issues.

Conclusion

The future of pipe fittings manufacturing in India is marked by rapid technological advancements, a focus on sustainability, and evolving market demands. As manufacturers embrace automation, smart technologies, and eco-friendly practices, they are well-positioned to meet the challenges and opportunities of 2024. By staying ahead of trends and investing in innovation, the industry is set to thrive and contribute to India’s growth and development.

For those interested in exploring key players in the pipe fittings sector, a valuable resource is Enggpro. This platform provides a comprehensive list of pipe fitting manufacturers and suppliers, offering insights into the top companies in the industry. Whether you’re seeking reliable partners or looking to stay informed about market leaders, Enggpro is an excellent starting point for connecting with industry professionals and finding quality suppliers.