Introduction

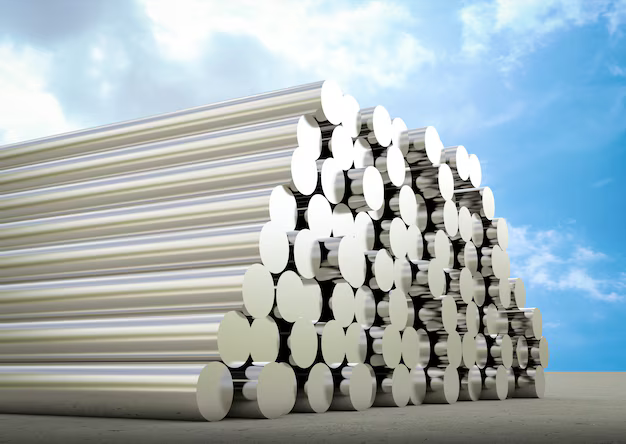

Stainless steel round bars are among the most commonly used industrial raw materials, prized for their strength, durability, and corrosion resistance. These bars are widely employed in various industries, including construction, automotive, aerospace, manufacturing, and marine applications. The unique properties of stainless steel make it a preferred choice for applications requiring high performance and longevity.

In this blog, we will delve into the benefits of stainless steel round bars, their manufacturing process, applications, and factors to consider when choosing the right supplier. Finally, we will provide a list of leading stainless steel round bar manufacturers and suppliers from Enggpro to help you find the best sources for your needs.

Benefits of Stainless Steel Round Bars

1. Corrosion Resistance

One of the most significant advantages of stainless steel round bars is their exceptional resistance to corrosion. Stainless steel contains chromium, which forms a protective oxide layer on the surface, preventing rust and degradation. This makes them ideal for use in industries exposed to moisture, chemicals, and extreme environments, such as marine, chemical, and food processing industries.

2. High Strength and Durability

Stainless steel round bars exhibit excellent tensile strength, which allows them to withstand heavy loads and harsh conditions without deformation or failure. They offer superior durability, ensuring long-lasting performance with minimal maintenance requirements.

3. Heat and Temperature Resistance

These bars maintain their mechanical properties even at high temperatures, making them suitable for applications in power plants, automotive exhaust systems, and industrial furnaces.

4. Aesthetic Appeal

Stainless steel round bars have a sleek and polished appearance, making them an excellent choice for architectural and decorative applications. Their smooth surface enhances the aesthetics of structures and finished products.

5. Versatility

Stainless steel round bars are available in various grades, sizes, and finishes, making them highly versatile for different applications. Whether used for machining, construction, or precision engineering, they can be customized to meet specific requirements.

6. Easy Fabrication and Machining

Stainless steel round bars are easy to cut, weld, and machine, allowing manufacturers to create complex shapes and components with high precision. Their machinability makes them a preferred material in the manufacturing and engineering industries.

7. Environmentally Friendly

Stainless steel is 100% recyclable, making it an eco-friendly choice. Many industries opt for stainless steel to reduce their carbon footprint and promote sustainability.

See Also Stainless Steel Round Bars: Types, Grades, and Uses

Manufacturing Process of Stainless Steel Round Bars

The production of stainless steel round bars involves several stages:

- Melting and Casting: Raw materials like iron ore, chromium, nickel, and molybdenum are melted in an electric arc furnace. The molten metal is then cast into semi-finished forms such as billets.

- Hot Rolling: The billets are heated and passed through rolling mills to achieve the desired diameter and shape.

- Heat Treatment: Processes like annealing, quenching, and tempering enhance the mechanical properties of the bars.

- Cold Finishing: Additional processes such as centerless grinding, peeling, and polishing ensure precision dimensions and surface finishes.

- Quality Testing: Stainless steel round bars undergo rigorous testing, including tensile strength, impact resistance, and non-destructive testing (NDT), to meet industry standards.

Applications of Stainless Steel Round Bars

1. Construction and Infrastructure

Stainless steel round bars are widely used in construction for reinforcement, structural components, and support frameworks. Their strength and corrosion resistance make them ideal for bridges, buildings, and high-rise structures.

2. Automotive Industry

Automobile manufacturers use stainless steel round bars for producing axles, shafts, fasteners, and engine components due to their durability, heat resistance, and anti-corrosive properties.

3. Aerospace Industry

In aerospace applications, stainless steel round bars are utilized for making aircraft parts, landing gears, and turbine components that require high strength and resistance to extreme temperatures.

4. Marine Industry

The marine environment is highly corrosive, making stainless steel the preferred choice for shipbuilding, offshore platforms, and marine hardware.

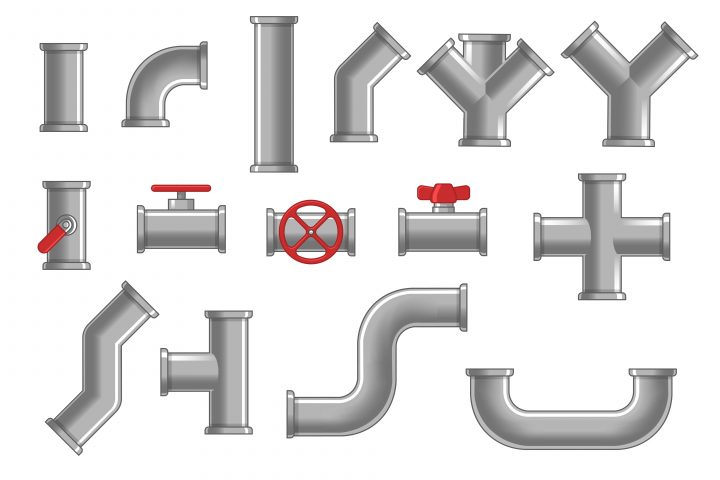

5. Oil and Gas Industry

Stainless steel round bars are extensively used in the oil and gas sector for drilling equipment, pipelines, valves, and offshore structures where exposure to extreme pressure and corrosive fluids is common.

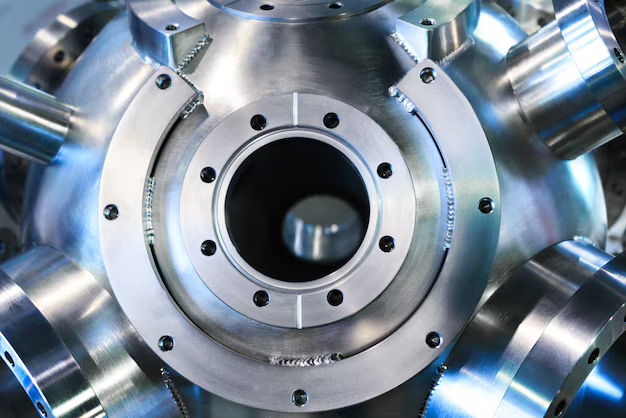

6. Manufacturing and Machinery

Precision engineering and industrial machinery require stainless steel round bars for manufacturing gears, bolts, and machine components. Their superior machinability and strength make them essential in heavy machinery production.

7. Food and Beverage Industry

Hygiene and cleanliness are crucial in the food industry. Stainless steel round bars are used in food processing equipment, dairy plants, and breweries due to their non-reactive nature and easy sterilization.

8. Medical Industry

Stainless steel round bars are utilized in medical instruments, surgical tools, orthopedic implants, and hospital furniture due to their biocompatibility and resistance to sterilization chemicals.

See Also The Essential Guide to Stainless Steel Round Bars: Properties, Uses, and Top Suppliers

Factors to Consider When Choosing a Stainless Steel Round Bar Supplier

When sourcing stainless steel round bars, selecting the right supplier is essential to ensure quality and reliability. Here are key factors to consider:

- Certifications and Quality Standards: Ensure the supplier adheres to international standards like ASTM, AISI, and ISO 9001.

- Product Range: Choose a supplier offering various grades, sizes, and finishes to meet your specific requirements.

- Customization Options: Some suppliers provide tailored solutions for special applications, including cut-to-length services.

- Delivery and Lead Time: Timely delivery is crucial to avoid project delays. Check the supplier’s logistics capabilities.

- Technical Support: Reliable suppliers offer expert guidance in material selection and application-specific recommendations.

- Competitive Pricing: Compare prices from multiple suppliers to get the best value without compromising on quality.

Conclusion

Stainless steel round bars are an essential component in numerous industries, offering unparalleled strength, corrosion resistance, and versatility. Their wide range of applications makes them indispensable in construction, automotive, aerospace, oil & gas, and many other sectors.

To ensure the highest quality and best service, sourcing from reputable manufacturers and suppliers is crucial. Enggpro provides a comprehensive list of trusted stainless steel round bar manufacturers and suppliers, making it easier for businesses to find the right products for their needs.

Leading Stainless Steel Round Bar Manufacturers & Suppliers on Enggpro

- Jindal Stainless Steel – Renowned for high-quality stainless steel products and a wide range of grades and sizes.

- Mukand Ltd. – Specializes in long stainless steel products, including round bars that meet international standards.

- Venus Wire Industries Pvt. Ltd. – Offers precision-engineered stainless steel round bars with superior quality control.

- Viraj Profiles Ltd. – A global exporter known for its comprehensive stainless steel product range.

- Bhansali Bright Bars Pvt. Ltd. – Provides high-quality stainless steel round bars with excellent machinability.

By choosing from Enggpro’s verified suppliers, you can ensure high-performance stainless steel round bars that meet your specific application requirements. Whether for industrial, commercial, or specialized applications, sourcing from a reliable platform like Enggpro ensures you receive top-quality products with competitive pricing and prompt delivery.

For more information and to explore trusted suppliers, visit Enggpro.