India, as one of the fastest-growing economies in the world, has undergone significant industrialization over the past few decades. This growth has been fueled by various sectors, including construction, energy, oil and gas, petrochemicals, and infrastructure. Among the many components that are crucial to these industries, welded pipes stand out as essential elements in modern engineering and manufacturing. Welded pipes, with their versatile applications and robust characteristics, play a vital role in ensuring the seamless operation of India’s industrial machinery and processes.

In this blog, we will explore the role of welded pipes manufacturers in India’s industrial growth, diving deep into the industry, its processes, significance, challenges, and the overall contributions made by Indian manufacturers in the global marketplace.

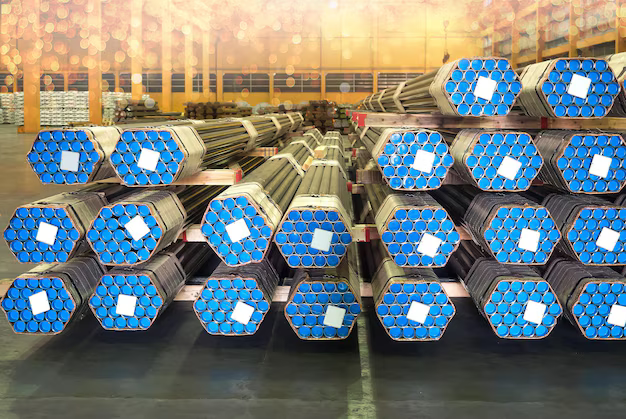

1. An Overview of Welded Pipes

Welded pipes are tubes that are made by welding the edges of steel strips or plates. These pipes are primarily used in various sectors for the transportation of liquids, gases, and other materials. There are two major types of welded pipes:

- Longitudinally Welded Pipes (L-SAW): These pipes are made by bending the plate into a cylindrical shape and then welding it along its length.

- Spirally Welded Pipes (H-SAW): These pipes are created by spirally coiling the steel strip and then welding it helically.

Compared to seamless pipes, welded pipes have a lower production cost and can be manufactured in a variety of sizes, making them highly adaptable to a wide range of industrial needs.

2. Key Sectors Driving Demand for Welded Pipes in India

a. Oil and Gas Industry

One of the largest consumers of welded pipes in India is the oil and gas sector. Welded pipes are crucial in transporting oil and gas across large distances, both onshore and offshore. India’s burgeoning energy needs, coupled with efforts to reduce dependency on foreign imports, have boosted the demand for pipelines, driving the growth of welded pipe manufacturing. Companies in India are increasingly investing in modern welded pipe technologies to meet stringent industry standards for transporting hydrocarbons.

b. Construction and Infrastructure

With India’s growing population and rapid urbanization, the construction and infrastructure sectors are booming. Welded pipes are commonly used in structural applications, such as for building frameworks, scaffolding, and construction support systems. Additionally, India’s government has been investing heavily in projects like roads, railways, airports, and smart cities, further increasing the demand for welded pipes. These projects require pipes for water, sewage, and gas pipelines, as well as steel structures used in bridges, flyovers, and stadiums.

c. Water and Wastewater Management

India faces significant challenges in managing its water resources. Efficient transportation of water to urban, industrial, and rural areas is a priority for the government. Welded pipes are used extensively in water treatment plants, desalination plants, and in the infrastructure that moves water to and from cities. The push towards better sanitation and clean water access, in alignment with programs like “Swachh Bharat Mission” and “Smart Cities Mission,” has resulted in a growing market for welded pipes for both fresh water and wastewater applications.

d. Automotive and Mechanical Industries

The automotive industry is another significant sector contributing to India’s industrial growth. Welded pipes are essential in the production of vehicle exhaust systems, chassis components, and other mechanical systems. India’s automotive manufacturing industry is robust, and welded pipe manufacturers have been able to supply high-quality materials that meet international standards, further propelling India’s export markets.

3. Welded Pipes Manufacturing Process

The production of welded pipes involves several critical steps, including material selection, forming, welding, testing, and finishing. Here is a breakdown of the essential stages involved:

a. Material Selection

The process begins with selecting the appropriate raw material, often steel strips or plates. The choice of material depends on the pipe’s application—whether it needs to resist corrosion, extreme pressure, or other environmental factors.

b. Forming

The steel strips are passed through a series of rollers, shaping them into cylindrical forms. The method of forming depends on the type of welded pipe being produced, either longitudinal or spiral.

c. Welding

Once the pipe is formed, the edges of the steel are welded together to create a strong, seamless bond. Different welding methods, such as Electric Resistance Welding (ERW) or Submerged Arc Welding (SAW), are employed based on the pipe’s specifications.

d. Testing

Quality control is a vital part of the manufacturing process. Pipes are tested for structural integrity, weld strength, and durability to ensure they meet industry standards. Non-destructive testing (NDT) methods, such as ultrasonic or X-ray testing, are commonly used to verify the integrity of the welds.

e. Finishing

Finally, the pipes are cut to the desired lengths and finished as per customer requirements. This may include coating, threading, or applying protective linings, depending on the application.

See Also Rise of Welded Pipes Manufacturers in India: Quality and Innovation in Focus

4. The Role of Indian Welded Pipes Manufacturers in Global Supply Chains

India has become a significant player in the global welded pipe industry. Several factors have contributed to this, including:

a. Cost-Effective Manufacturing

India’s competitive labor costs and access to raw materials have made it a cost-effective hub for welded pipe manufacturing. Indian manufacturers can produce high-quality welded pipes at a lower price than many international competitors.

b. Adoption of Advanced Technologies

Indian welded pipe manufacturers have rapidly adopted advanced technologies such as automated welding processes, quality testing protocols, and improved metallurgical techniques. This enables them to meet stringent international standards and cater to global markets.

c. Government Support and Infrastructure Development

Government initiatives, such as Make in India and Atmanirbhar Bharat, have provided significant support to the Indian manufacturing sector. Incentives like tax breaks, subsidies, and improved infrastructure have allowed manufacturers to increase production capacities and target exports.

d. Export Markets

India exports welded pipes to countries across Asia, Europe, the Middle East, and North America. Indian manufacturers have successfully penetrated these markets due to their ability to produce a wide variety of welded pipes, including those used in high-stress applications such as oil and gas pipelines.

5. Challenges Faced by the Indian Welded Pipe Industry

Despite the impressive growth of the welded pipe sector, manufacturers in India face several challenges that could impact the industry’s future. These include:

a. Raw Material Price Fluctuations

Steel, the primary raw material used in welded pipe production, is subject to volatile pricing. Fluctuations in global steel prices can affect the cost of production, reducing profit margins for manufacturers.

b. Competition from Seamless Pipes

While welded pipes offer many advantages, seamless pipes are often preferred for certain high-pressure applications. Indian manufacturers must continue to innovate and improve the strength and reliability of their welded products to remain competitive against seamless pipe alternatives.

c. Environmental Regulations

As environmental concerns grow, the pressure to reduce carbon footprints and adopt sustainable manufacturing practices is increasing. Compliance with these regulations can be costly and may require significant investment in new technologies and processes.

d. Global Economic Factors

Global supply chain disruptions, trade restrictions, and tariff changes can impact the export of welded pipes. Indian manufacturers must navigate these complexities while maintaining their foothold in international markets.

6. The Future of Welded Pipe Manufacturing in India

India’s welded pipe industry is poised for continued growth in the coming years. The country’s focus on infrastructure development, energy security, and expanding its industrial base will drive demand for welded pipes across various sectors. Here are some trends that will shape the future of the industry:

a. Innovation in Materials and Coatings

Research and development in new materials, such as corrosion-resistant alloys, will play a crucial role in the future of welded pipes. Innovations in protective coatings, such as advanced polymers and anti-corrosion layers, will extend the lifespan of pipes and enhance their performance in harsh environments.

b. Expansion of Domestic and International Markets

As India’s industrial base expands, the domestic market for welded pipes will grow significantly. Additionally, Indian manufacturers will continue to target international markets, particularly in regions with high infrastructure development demands, such as Africa and Southeast Asia.

c. Sustainability and Green Manufacturing

With a global push toward sustainability, Indian welded pipe manufacturers will need to adopt greener production processes. This may include energy-efficient machinery, recycling of materials, and reducing waste. Companies that can integrate eco-friendly practices into their manufacturing will likely gain a competitive edge.

Conclusion

Welded pipes play a pivotal role in India’s industrial ecosystem. From transporting oil and gas to forming the backbone of structural frameworks in construction, their applications are vast and critical. Indian welded pipe manufacturers have risen to the challenge of meeting both domestic and international demands, contributing significantly to the country’s industrial growth.

While challenges remain, the future of the industry looks promising. With a focus on innovation, sustainability, and expanding markets, India’s welded pipe manufacturers are set to continue their journey as essential contributors to the nation’s—and the world’s—industrial progress.

For those looking to source welded pipes for various applications, you can find a comprehensive list of Welded Pipes Manufacturers and Suppliers on Enggpro, a leading platform connecting buyers with top suppliers across the globe.