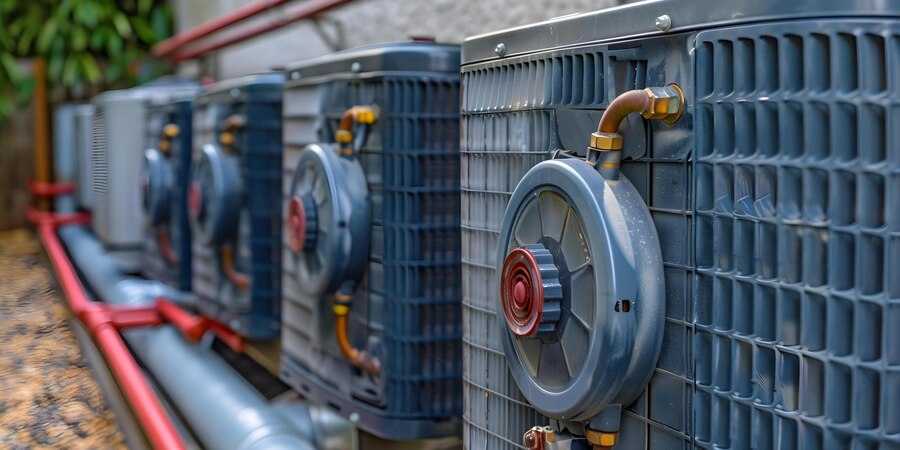

Heat exchangers are vital components in various industries, facilitating efficient heat transfer between fluids. Whether for HVAC systems, chemical processing, or power generation, selecting a reliable heat exchanger manufacturer is crucial for ensuring performance, longevity, and safety. Here’s what to consider when choosing a heat exchanger manufacturer:

1. Experience and Expertise

A manufacturer’s experience in the industry is a significant factor in determining their reliability. Look for companies with a proven track record of designing and producing heat exchangers. Experienced manufacturers are more likely to understand the complexities of different applications and offer solutions tailored to your specific needs. Evaluate their portfolio and case studies to gauge their expertise and the range of industries they serve.

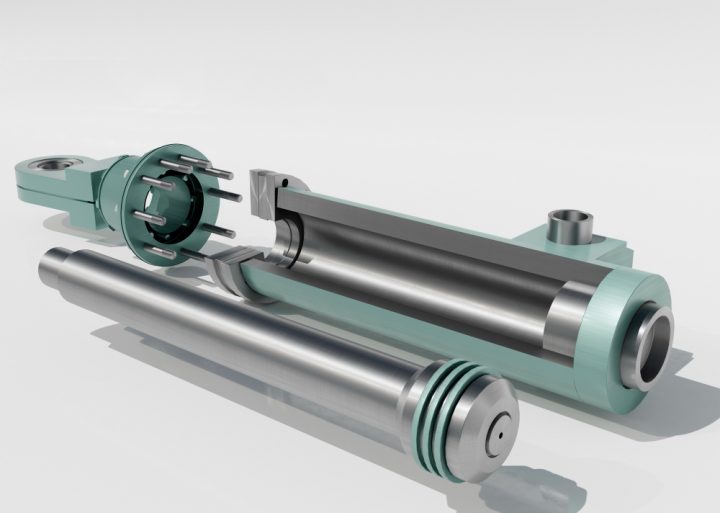

2. Quality of Materials and Construction

The quality of materials used in heat exchanger construction directly impacts its performance and durability. A reliable manufacturer should use high-grade materials that can withstand the operational conditions, such as high temperatures, pressures, and corrosive environments. Check if the manufacturer adheres to international standards and certifications, such as ASME, ISO, or API, which ensure the quality and safety of their products.

3. Customization Capabilities

Heat exchangers often need to be customized to meet specific requirements. A good manufacturer should offer customization options to address your unique needs. This includes different types of heat exchangers (shell and tube, plate, air-cooled, etc.), sizes, materials, and configurations. Ensure that the manufacturer has the capability to design and build bespoke solutions that align with your operational demands.

4. Technical Support and Service

Reliable manufacturers offer excellent technical support and after-sales service. This is crucial for troubleshooting, maintenance, and ensuring the heat exchanger operates efficiently throughout its lifespan. Look for manufacturers who provide comprehensive support, including installation guidance, regular maintenance, and timely repairs. A strong support network ensures that you can address any issues quickly and minimize downtime.

5. Innovation and Technology

The heat exchanger industry continually evolves with advancements in technology and materials. A reputable manufacturer should invest in research and development to incorporate the latest innovations into their products. This includes advanced heat transfer technologies, improved materials, and energy-efficient designs. Check if the manufacturer adopts new technologies that can enhance performance and reduce operational costs.

6. Reputation and Reviews

A manufacturer’s reputation in the industry can be a good indicator of their reliability. Look for customer reviews, testimonials, and case studies to get an idea of their performance and customer satisfaction. You can also seek recommendations from industry peers or consult with professional associations. A manufacturer with a solid reputation is more likely to deliver high-quality products and services.

7. Certifications and Compliance

Ensure that the manufacturer complies with relevant industry standards and regulations. Certifications such as ISO 9001 for quality management systems or specific certifications for heat exchangers demonstrate a commitment to quality and reliability. Compliance with safety standards and environmental regulations is also important to ensure that the products are safe and environmentally friendly.

8. Cost and Value for Money

While cost is an important consideration, it should not be the sole factor in your decision. A lower price may sometimes mean lower quality or reduced support. Evaluate the overall value for money, including the quality of materials, design, customization options, and after-sales service. A well-made heat exchanger with reliable support may have a higher upfront cost but offer better long-term performance and lower maintenance costs.

9. Delivery and Lead Times

Timely delivery of heat exchangers is crucial for maintaining your project schedule and operational efficiency. Check the manufacturer’s lead times and their ability to meet deadlines. Reliable manufacturers should provide clear delivery schedules and have mechanisms in place to handle any potential delays. Timely delivery ensures that you can implement your heat exchanger without unnecessary interruptions.

10. Global Presence and Supply Chain

For projects with international requirements, consider manufacturers with a global presence or strong supply chain networks. This ensures that you can access their products and services from different locations and that they can support global operations. A manufacturer with a well-established supply chain can provide consistent quality and availability of products, regardless of your location.

Conclusion

Choosing a reliable heat exchanger manufacturer is essential for ensuring optimal performance, efficiency, and longevity of your heat exchangers. Consider factors such as experience, material quality, customization capabilities, technical support, and innovation when making your decision. A manufacturer that meets these criteria is more likely to provide high-quality products and services that align with your needs.

To discover top heat exchanger manufacturers and suppliers in India, visit Enggpro. Enggpro connects you with leading companies that offer a wide range of heat exchangers, from standard models to custom solutions, ensuring you find the right fit for your application. Explore their network to find reputable manufacturers who can meet your specific requirements and help you achieve optimal performance in your operations.